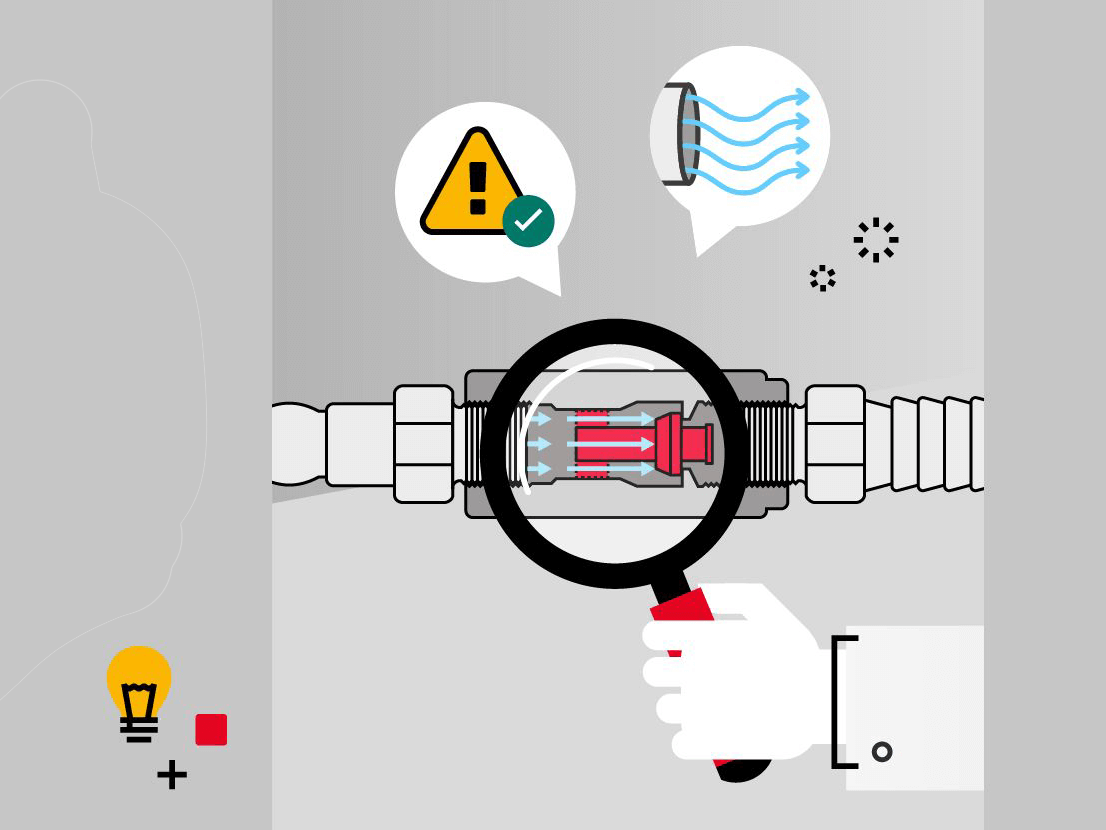

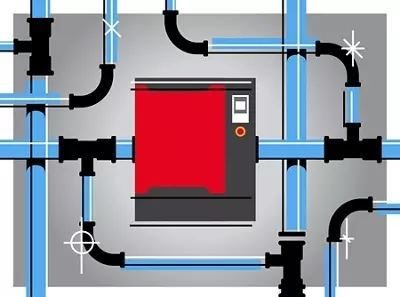

For many businesses, preserving energy and becoming more sustainable have become top priorities. That not only saves them money but also makes them more competitive in the future, when demand for “green” products and services will only increase. Not just because governments mandate greater sustainability but also because you, our customers expect it. Here, we talk to our experienced Sales Engineer, Romain, who has a strong background in helping our partners with energy efficient compressed air options to get the most out of their business. Read More…

Water for All: Ash Air and ADRA Empower Communities in Vanuatu

Since 1979, we at Ash Air have been committed to serving the kiwi industry with high-quality products and uncompromising service, including brands such as Chicago Pneumatic, ALUP, and Pneumatic. But we also care about the local community across Aotearoa.

Beginning of 2023 Ash Air partnered with the Adventist

Development and Relief Agency’s (ADRA) initiative to bring clean water to communities Vanuatu. This partnership support the broader Water

For All initiatives under the Atlas Copco Group. Many of

these communities face significant challenges due to limited access to safe water, impacting health, education, and livelihoods. By

delivering clean water, sanitary facilities, and hygiene education, ADRA’s program helps reduce disease and build stronger, more

resilient communities.

Friday, July 18th, the Ash Air team organized an event across New Zealand, including Highbrook, Rosedale, Hamilton, Christchurch, and

Dunedin, in support of an initiative by coming together to support ADRA. All Employees gathered at their local offices to show their support

and participate in fun activities.

On the day of the event, our teams gathered with great enthusiasm. To embody the spirit of generosity, employees wore blue and donated gold

coins to support the cause. At Ash Air, we believe in helping our local communities, and the team shared a common goal of helping the

community in Vanuatu as we gathered around the break room for morning tea.

To inspire a spirit of collaboration and friendly competition, we organized a photo contest, with the winners eligible to receive exciting

prizes. Our employees had a great time engaging in activities across all our offices. It was truly inspiring to see the Ash Air team come

together to support this meaningful cause.

.png)

.jpeg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.jpg)

.png)

.png)

.png)

.png)

![Revisit // [VIDEO] A conversation with Jess, female Service Engineer at Ash Air](/media/website_posts/228/Screenshot-2023-02-24-084935.png)