Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Air compressors are helpful for an enormous range of applications such as air filling, packaging, tools, HVAC control, and more! One

possible drawback is the amount of electricity they use; air compressors can be a huge drain on energy if used inefficiently. If you are

running them too long, allowing leaks to exist, or using the wrong type of compressor, you are wasting energy and money. This article will

go over some of the biggest power-wasters and how to

stop/prevent them!

One

of the most common ways to waste energy with air compressors is to operate with no set schedule. Every business works at different hours

and has varying levels of air demand, but if you only need compressors for 4 hours out of an 8-hour work day, it only makes sense that you

would only want them running for 4 hours.

One

of the most common ways to waste energy with air compressors is to operate with no set schedule. Every business works at different hours

and has varying levels of air demand, but if you only need compressors for 4 hours out of an 8-hour work day, it only makes sense that you

would only want them running for 4 hours.

Unfortunately, manually turning compressors on and off is not always possible due to time and space restrictions. Luckily, Chicago Pneumatic

thought of that. We carry several state-of-the-art compressor models with control panels that allow the user to set a schedule on the

machine itself.

Another problem that is more common than you may think is air compressor leakage. Leaks are not always easy to see or hear and can

contribute to energy waste and ineffectiveness of compressors.

Depending on usage, a ¼” air leak at 100psi could cost over $2500 in wasted energy over the span of a year. It is recommended to have a leak

detection professional check your compressor(s) periodically so you can be sure you aren’t wasting any energy. Duct tape may work as a short

term solution, but it doesn’t fix the problem permanently.

Single-stage air compressors are often used in HVAC applications despite their inefficient operation. They are either on or off, with no variance in power, so if you only need a little air they will turn on full blast. When possible, variable-speed compressors should be used, as they will attempt to match delivery with what is being demanded and not use as much power when less is required. CP carries variable-speed rotary screw compressors that will save energy by operating when and how powerfully you need them to.

Though it is a very helpful tool, compressed air cannot do everything. You could be wasting money and breaking OSHA regulations without even knowing it. One of the most common misuses of compressed air is debris clearing. Unless psi is 30 or less, clearing things from the ground with compressed air is an OSHA violation. In addition, dusting debris off yourself or another person is forbidden regardless of pressure. There are other, less expensive/dangerous ways to clean, so perhaps save the compressed air for more vital applications.

Another place air could be wasted is in the piping of air from the compressor to its destination. Often, processes and machinery are changed or moved without considering what inefficiencies that could create, especially if you are operating multiple compressors from a centralized location. Periodically review your piping system to make sure air is getting from the compressor to its final destination in as short a distance as possible. The further air travels, the more energy it takes, so shortening the pipeline is a great way to save energy!

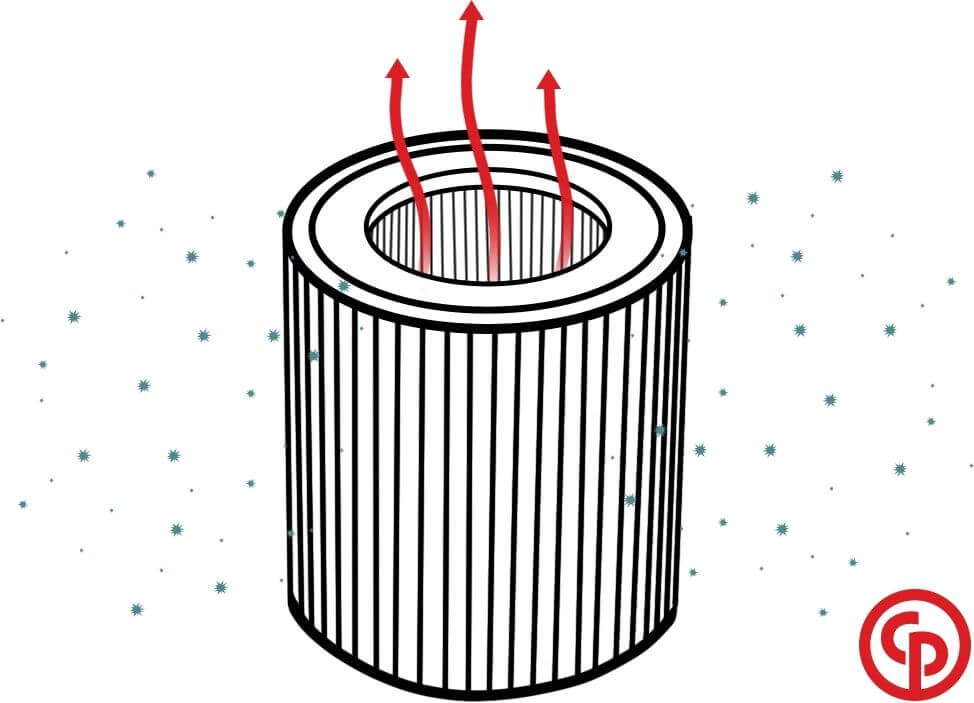

One of the most helpful tips for saving energy is to change filters according to a recommended maintenance schedule. Most compressors say how often you should be replacing filters, and those schedules, based on testing and rigorous calculations, should be paid attention to! If you use filters in other parts of your facility, those should also be systematically replaced according to a schedule.

Blocked

filters, whether they are for air, oil, water, or any other fluid, prevent a portion of fluid from passing through. It is extremely

inefficient to operate with blocked filters, which is why replacing them is a great way to save energy. All of the other general

maintenance items of an air compressor should be checked regularly as well. Doing so will improve performance and extend the lifespan of

an air compressor.

Blocked

filters, whether they are for air, oil, water, or any other fluid, prevent a portion of fluid from passing through. It is extremely

inefficient to operate with blocked filters, which is why replacing them is a great way to save energy. All of the other general

maintenance items of an air compressor should be checked regularly as well. Doing so will improve performance and extend the lifespan of

an air compressor.

By implementing just a few of these energy saving tips, you could save thousands of dollars each year! Many operators miss many of these energy saving opportunities because they are trying to save money in the moment, but they all cost more in the long run. Fixing a leaky valve is not as expensive as all the energy it wastes. If you remember two things from this blog post, they should be to keep up with regular compressor maintenance and to only turn on your air compressor when it’s needed.

Ash Air is here for your business longevity!

Do you have an idea for our #expertcorner? Let

us know!

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a reputation for quality and reliability.We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, Alup, Pneumatech, and Quincy compressors are used extensively around the world in industries ranging from oil and gas to food, automotive and farming, and we bring you these world class compressors here in the land of the long white cloud.Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported by a 13 locations nationwide, Ash Air offers one of the widest selections of compressed air equipment and parts available today in New Zealand.

With Ash Air compressors, you can count on reliability and high performance for even the most demanding applications. We focus our efforts on the following:

Talk to the team today:

Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Maintenance budget: 8 factors to consider

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for maintenance can have potentially disastrous consequences. Read More…

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause complete dryer failure. Read More…