This customer had historically used liquid nitrogen within their processes, and found themselves in the unfortunate position.

When renegotiating their LIN contract renewal with their supplier, that LIN pricing was increasing 2.5 times, as well as further uncertainty that their volume requirements could even be met going forward. They were left with 60 days to find an alternate solution.

Ash Air have, for a number of years, maintained the compressed air systems for a customer operating within the dairy industry.

This customer had historically used liquid nitrogen within their processes, and found themselves in the unfortunate position, when renegotiating their LIN contract renewal with their supplier, that LIN pricing was increasing 2.5 times, as well as further uncertainty that their volume requirements could even be met going forward. They were left with 60 days to find an alternate solution.

The solution:

Ash Air were tasked to size a suitable on-site nitrogen generation system, allowing them independence from third party supply, and an

overall saving to their production costs.

Due to the urgency of the project, a Pneumatech PSA unit was air freighted from Europe.

Local engineering work immediately began on a 40’ high cube shipping container to house the new standalone system, including

ventilation, ducting and AIRnet pipework.

An ALUP IVR compressor, dryer and ancillary equipment were selected to accompany the nitrogen generator and ensure optimum performance,

reliability and energy savings.

Installation and commissioning of the containerized solution was achieved 48 days from initial project commencement, resulting in the

customer avoiding having to sign the exorbitant new LIN contract.

The net result was a ROI of less than 7 months for the customer, independence from third party supply with full control of their

production capacity, reduced environmental impact of truck deliveries of LIN, an energy efficient solution and an overall saving to their

production costs.

Gallery:

.jpg)

.jpg)

On-site generation offers convincing benefits compared to liquid or gaseous N2 deliveries.

1. Cost efficiency

Producing your own nitrogen with the purity you need allows you to significantly reduce your cost

of gas

2. Sustainability

Eliminate the transport emissions that nitrogen deliveries generate. In addition, Pneumatech’s

on-site generation solutions are super efficient, minimizing your energy use and your environmental footprint.

3. A reliable nitrogen supply

No need to count on external vendors. On-site generation gives you complete control over

your nitrogen supply.

4. No logistics

Say goodbye to always monitoring your N2 supply, working with vendors, and tracking

and handling deliveries.

Empower your operations with the intelligent choice of producing nitrogen on-site. Opting for an on-site nitrogen generator in New Zealand is a superior, cost-efficient, and sustainable alternative to traditional gas deliveries. Switch from Liquid Nitrogen to On-Site Generation and Cut Your Operating Cost Down.

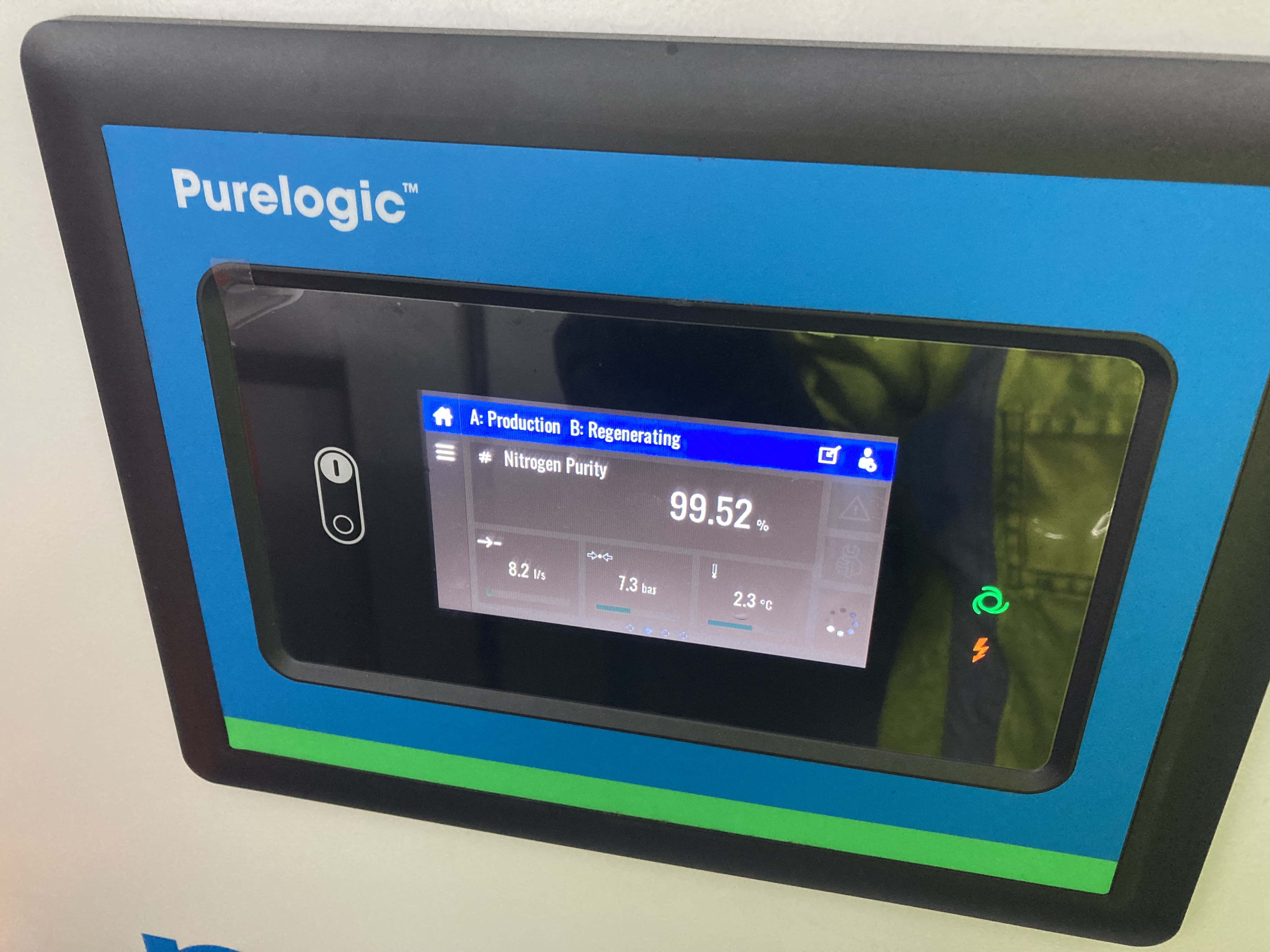

PSA technology

Utilizing PSA technology, Pressure Swing Adsorption (PSA) effectively isolates nitrogen from compressed air by utilizing adsorbent

materials. By passing the air through a vessel containing Carbon Molecular Sieves (CMS), the oxygen is captured, allowing only nitrogen of

up to 99.999% purity to exit. PSA generators are well-suited for applications requiring high-flow and high-purity nitrogen.

We're proud to offer ALUP rotary screw compressors. Our assortment of screw air compressors encompasses fixed speed, variable speed, and our highly efficient Evoluto model. Our rotary screw air compressors cater to a broad spectrum of requirements.

If you are in search of top-quality screw compressors, ALUP stands as the ideal air compressor company for you. Explore the diverse range

of rotary compressors on this page or reach out to us today for assistance in selecting the optimal screw compressor for your

operations.

Refrigeration dryers are widely used for eliminating moisture from compressed air, making them essential for preventing corrosion in air

systems and safeguarding equipment and final products.

As the predominant drying technology for compressed air, refrigeration dryers find applications across various industries.Pneumatech refrigeration compressed air dryers, protecting your compressor systems!

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a reputation for quality and reliability. We look after all things compressed air for your business!

Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Ash Air offers one of the

widest selections of compressed air equipment and parts available today in New Zealand.

With Ash Air compressors, you can count on reliability and high performance for even the most demanding applications. We focus our efforts on the following:

Ash Air's range of Chicago Pneumatic, Alup air compressors, Pneumatech industrial gases and Atlas Copco vacuum pumps are used extensively around the world in industries ranging from oil and gas to food, automotive and farming.

.png)