Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

A common questions asked is why do I need an air dryer for my compressor? Typically, air compressors produce water, and although the water

can be drained, there can still be aerosol and vapour droplets that are present. This is because water cannot be compressed. Water can

damage your compressor by corroding the valves, pipes and machinery controls, which will cost you time and money to resolve. In

the long run, the cost of a new compressor is a small price to pay compared to the loss of production that could potentially arise due to

water damage in your compressor.

When sizing an air dryer that keeps up with your application needs; it is important to get the right fit. A dryer that is too large will

cause harmful wear and tear long before normal, opposed to having an undersized dryer can lead to poor air quality

downstream.

What is the desired dew point (how dry compressed air needs to be – this will determine whether it is a refrigerated or desiccant style

dryer)?

• How much CFM will your compressor be sending through the dryer, and at what pressure?

• What are the ambient conditions of the dryer (ambient temperature, elevation, etc.)?

• What is the inlet temperature of the air going into the dryer?

Answering these few questions will give you a good start on selecting the right dryer technology and the appropriate size for your

compressor.

Remember, a desiccant dryer consumes 2% -20% of your CFM as purge air during the regeneration cycle of the vessels. With that in mind, you

will need to make sure you make the necessary arrangements. If it is a new install, the compressor will need to be sized appropriately to

compensate for the CFM loss during the purge cycle. If it is an existing install, you may have to upgrade the compressor. Ambient conditions

and correction factors also come into play.

Another thing to think about is the upfront costs of purchasing the air dryer and its installation aren’t the only costs that are incurred

in total. There are other costs that also need to be considered here, such as additional energy consumption and, the way the dryer is

regenerated (in case of desiccant air dryers).

Air compressors are a significant investment, crucial for many businesses operations through New Zealand, and the world, and sometime

they need to power some very important tools.That being said, keeping your compressor in tip top shape, regular services, having an air

dryer etc, ensures a longer lifetime of your compressor and will increase your production levels by reducing equipment failure issues

due to corrision of components. In conclusion, air dryers are worth every penny spent.

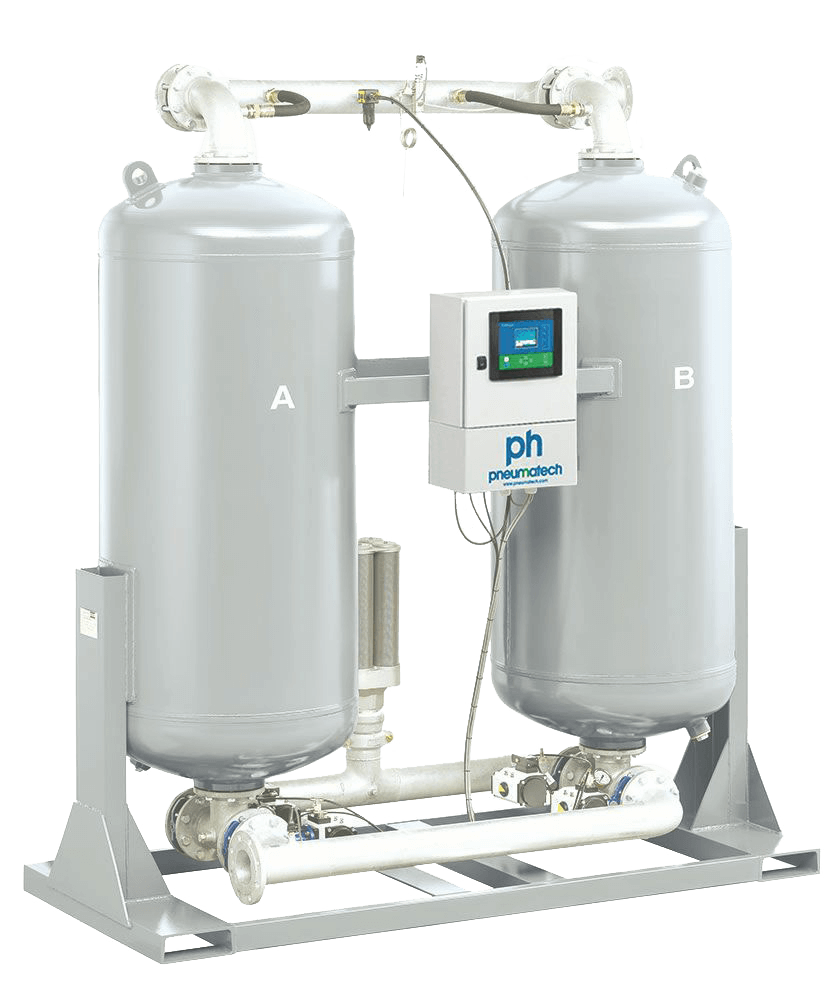

At Ash Air we stock top quality compressed refrigerated air dryers, desiccant air dryers. air receivers, and in-line filtration to give the best possible air quality your compressor can supply. Ash Air has a range of quality cycling and non-cycling Pneumatech refrigerated dryers for your air compressors.

Our innovative desiccant dryers give customers efficient protection against the presence of any humidity in the air, which often is the

source of pipe corrosion and decreased efficiency of equipment and tools. We sell all the connections and plumbing components commonly

used in New Zealand, and our comprehensive selection of compressed air filters is based on a unique, enhanced media to efficiently reduce

all types of contamination.

Here at Ash Air, we offer BA 15-310 HE Breathing Air Purifiers. The Pneumatech solution for Industrial Breathing Air applications, build to

exceed standards. The Breathing Air Dryer range assures safe working environment in a wide range of applications. Built to exceed standards,

Breathing Air Dryers provide certified breathing air, even in situations with polluted intake air to ensure personnel safety at all times.

The Ash Air range of advanced technology 360-1080 m3/hr and 1188-10800 m3/hr adsorption air dryers are for customers who have a focus on

energy efficiency and low operating costs, while maintaining the highest standards in air purity. Our Pneumatech blower purge air dryers use

heated blower purge air to remove moisture from the desiccant material, which means no purge loss during regeneration.

Ash Air has a range of quality cycling and non-cycling Pneumatech refrigerated dryers for your air compressors.Our non-cycling Pneumatech

refrigerated dryers offer a reliable and economic solution for removing moisture from your compressed air system. These refrigerated dryers

for air compressors are easy to install, offer energy savings, prevent pressure losses, are equipped with rotary compressors and R410A

refrigerant, and have improved connectivity features.

Do you have an idea for our #expertcorner? Let

us know!

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a reputation for quality and reliability.We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, Alup, Pneumatech, and Quincy compressors are used extensively around the world in industries ranging from oil and gas to food, automotive and farming, and we bring you these world class compressors here in the land of the long white cloud.Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported by a 13 locations nationwide, Ash Air offers one of the widest selections of compressed air equipment and parts available today in New Zealand.

With Ash Air compressors, you can count on reliability and high performance for even the most demanding applications. We focus our efforts on the following:

Talk to the team today:

Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Maintenance budget: 8 factors to consider

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for maintenance can have potentially disastrous consequences. Read More…

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause complete dryer failure. Read More…