Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Did

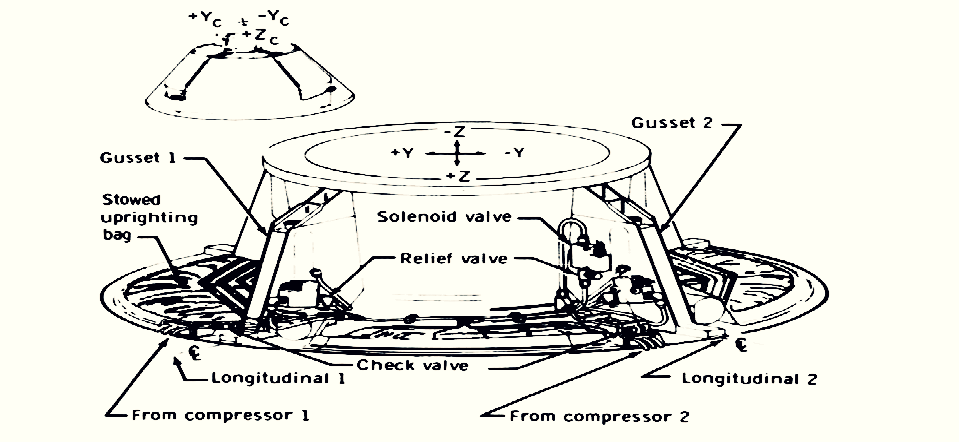

you know that Chicago Pneumatic helped man land on the moon? Notice in this photo of the Apollo 11 landing what appear to be "soccer

balls" on top of the capsule. They were inflated through a compressor specially developed by Chicago Pneumatic for NASA.

Did

you know that Chicago Pneumatic helped man land on the moon? Notice in this photo of the Apollo 11 landing what appear to be "soccer

balls" on top of the capsule. They were inflated through a compressor specially developed by Chicago Pneumatic for NASA.

At exactly 12:50 pm on July 24, 1969, the command module Columbia returned home the first humans to walk on the moon. Opening its parachutes after re-entrying the atmosphere at 40,320 km/h, the capsule gently plunged into the Pacific waters about 2,000 km from Hawaii.

The function of these inflatable bags was not related to cushioning the fall, but rather to ensure that the module was hatched upwards. Due to its design, it would float without the bags, but it could do so both with the exit hatch up and down (under water), which would be a serious problem for astronauts Neil Armstrong, Buzz Aldrin and Michael Collins. That's how NASA designed the system that was inflated by a small air compressor, after landing, causing the hatch to turn upwards.

The technology developed by Chicago Pneumatic had exceptional characteristics for the time:

- Ability to generate large amount of air in a short time.

- Extremely compact size.

- Very low weight.

- Resistance to large variations in temperature and pressure (including vacuum).

- Resistance to intense vibrations.

Of the many memorable achievements Chicago Pneumatic has contributed to success, this is perhaps the most proud and technically challenging. And without a doubt, this is the farthest portable compressor to date.

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a

reputation for quality and reliability.We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, Alup, Pneumatech, and Quincy compressors are used extensively around the world in industries

ranging from oil and gas to food, automotive and farming, and we bring you these world class compressors here in the land of the long white

cloud.Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported by a 13 locations

nationwide, Ash Air offers one of the widest selections of compressed air equipment and parts available today in New Zealand.

With Ash Air compressors, you can count on reliability and high performance for even the most demanding applications. We focus our

efforts on the following:

Talk to the team today:

Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider.

Read More…

Maintenance budget: 8 factors to consider

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire

lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for

maintenance can have potentially disastrous consequences.

Read More…

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause

complete dryer failure.

Read More…

Do you have an idea for our #expertcorner? Let

us know!

Who we are and how Ash Air can help your business!

Reliability and Efficiency

Read more from our #expertcorner