Nationwide Air Compressor and Vacuum Pump Services

Did you know you can book a service online?

Businesses small and large all over New Zealand trust us to service and look after their compressed air and

vacuum systems.

Businesses small and large all over New Zealand trust us to service and look after their compressed air and

vacuum systems.

Here at Ash Air, we offer second-to-none service and deliver sustainable solutions that increase customer productivity. Ash Air has been

maintaining New Zealand's compressed air and vacuum systems for more than 40 years.

Remote monitoring

Preventative maintenance

Vacuum pump services

Overhauls

Compressor and pipework installations

Hire fleet and leasing solutions

Leak detection's and energy audits

Breakdown recovery and emergency air.

With nationwide coverage, you can count on us as your compressed air specialists.

Wherever you are when you have a breakdown, our engineer will be there to support you 24/7.

We offer second-to-none services and spare parts for all brands.

With a small fee, we take care of your compressor so you relax and focus on your business, not the equipment.

Regular maintenance on your air compressors ensures that they perform at their best. It also extends the life

of the machines and reduces the risk of breakdown. The parts that need to be serviced regularly are such as air filters, oil filters,

oil, and belts.

Ash Air has been maintaining New Zealand's compressed air and vacuum systems for more than 40 years. Combining that with our extensive stock of parts covering all brands, you can be sure that our service is second-to-none. Call us now to schedule a service or ask about a customised service contract.

When you choose an Ash Air overhaul for your vacuum pump or blower the result is a pump that performs like new but has improved reliability!

We recommend for continuity of supply and efficient operation of your compressor it's crucial that your vacuum pump or blower is serviced

regularly.

Ash Air has a large and experienced team of specialist engineers who can repair, refurbish, overhaul and rebuild your air compressors and vacuum pumps, no matter what brand they are. We take pride in the quality of our service and in our dedication to help our customers solve their problems. This is why we are considered a business partner by our customers!

Talk to us today for expert advice and support for your next vacuum service and overhaul.

We sell, install, and service air compressors, vacuum pumps, and medical gas equipment. We also build pipe-work systems and make sure that your compressor room is suitable for the compressors to work well.

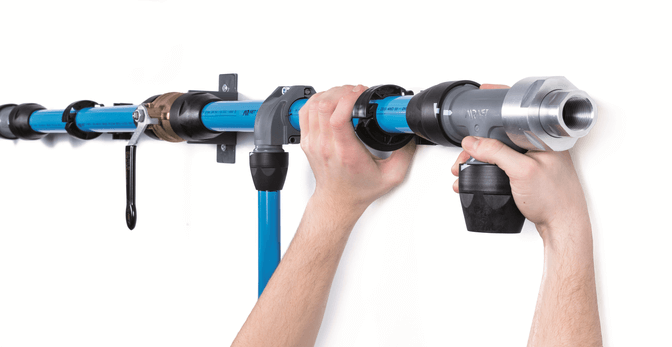

We offer AIRnet Piping Solutions. AIRnet is a fast, easy and reliable piping system, designed for compressed air, vacuum, and other inert gas applications from the source to the point of use with the lowest total cost of ownership.

More than 5,500 businesses all over New Zealand trust us to set-up, upgrade, and look after their compressed air and vacuum systems. We have helped them save costs, improve performance and achieve maximum efficiency.

Ash Air offers modern portable diesel compressors, pumps, blowers, generators, light towers for hire and lease across New Zealand to get you out of your compressed air and vacuum pump crisis.

Our full range of compressed air equipment available for loan or hire is highly beneficial for your business, especially when it is crucial to maintain production if your equipment has experienced failure, or is needing to be refurbished.

We offer modern portable diesel compressors, pumps, blowers, generators, light towers for hire across New Zealand. Don't hesitate to call us about our range of hire and rental equipment.

With our advanced tools for leak detection and data-logging, Ash Air can detect leaks and analyse your energy consumption. We will provide you with a comprehensive and easy-to-understand report and recommend the right solution for your system and save you money.

Ash Air can tailor a compressed air audit to suit your needs. If a walk through audit is sufficient one of our team of trained staff can carry this out, and feed this information back to you in a professional report with actions and recommendations.

Compressed air leaks can commonly account for 20-50% of a plant’s total compressed air consumption. Most leak detetion programs that are carried out do not offer this service as standard but at Ash Air we can save you money from the minute we start on your site.

Here at Ash Air, we provide the highest quality breakdown recovery and emergency air services. The Ash Ash team are available 24/7, when and where you need us! We strive for minimum downtime of your machine when the unfortunate occasion of a breakdown occurs.

Our compressor breakdown service means that should you have any issues with your compressed air system, the team at Ash Air will be available to visit your location, anytime, anywhere, and offer expert advice.

We have more than fifty qualified service engineers working throughout the country, and with nationwide coverage, we're here for you and your business' longevity around the clock.

An Ash Air SCOPE Service Agreement is formulated for customers who want to devote valuable resources to their core business, customers who want to benefit from the certainty of fixed maintenance costs, air compressor security and reducing any risk of unscheduled downtime.

Our Service Agreements provide peace of mind that the air compressor will remain in optimum and reliable condition to provide compressed air to meet the demand at all times at the most equitable possible cost.

If you are wondering about how to get the most out of your compressor, in the most cost-effective way, talk to us about SCOPE, the service plan that will make your life easy!

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider.

.jpeg)

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for maintenance can have potentially disastrous consequences.

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause complete dryer failure.

Using nitrogen is not about fully replacing CO2, but it can reduce their consumption of CO2 by close to 70%. Using nitrogen is about sustainability. Creating your own nitrogen is easy and will reduce the use of a greenhouse gas, which is better for the environment. It will also save you money as early as month one adding that savings to your bottom line.

ICONS: Intelligent Connectivity System: The insight into your compressed air system, wherever you are. Learn More about ICONS in this article here!

A question that is occasionally asked by our customers to Ash Air is 'what is the cost of compressed air?' This article looks at the product costs involved with compressed air, as well as minimising the energy cost of compressors and cost allocation. When looking at these factors, we need to realise what causes dropped efficiency of your compressor, leading to increased costs of compressed air.