Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

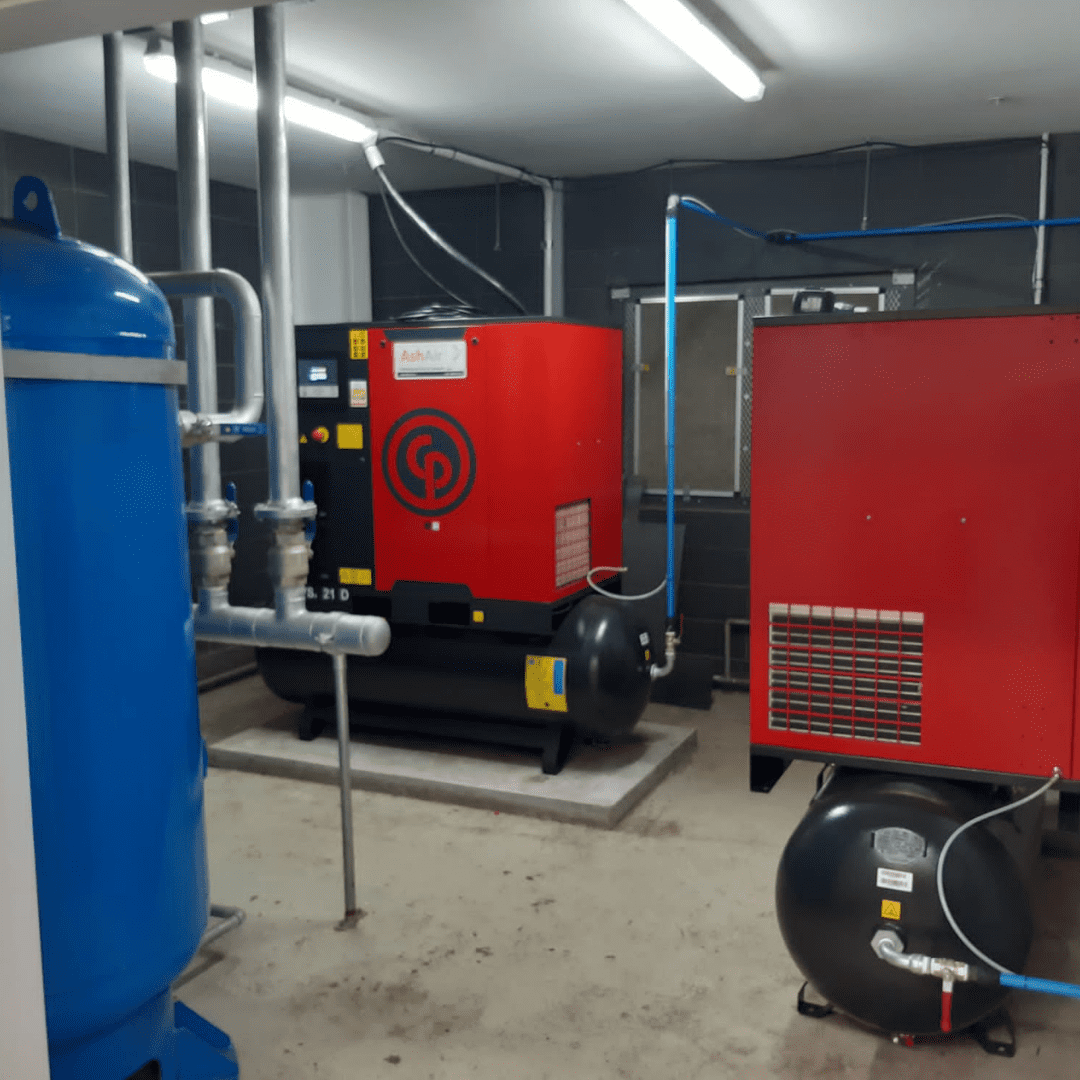

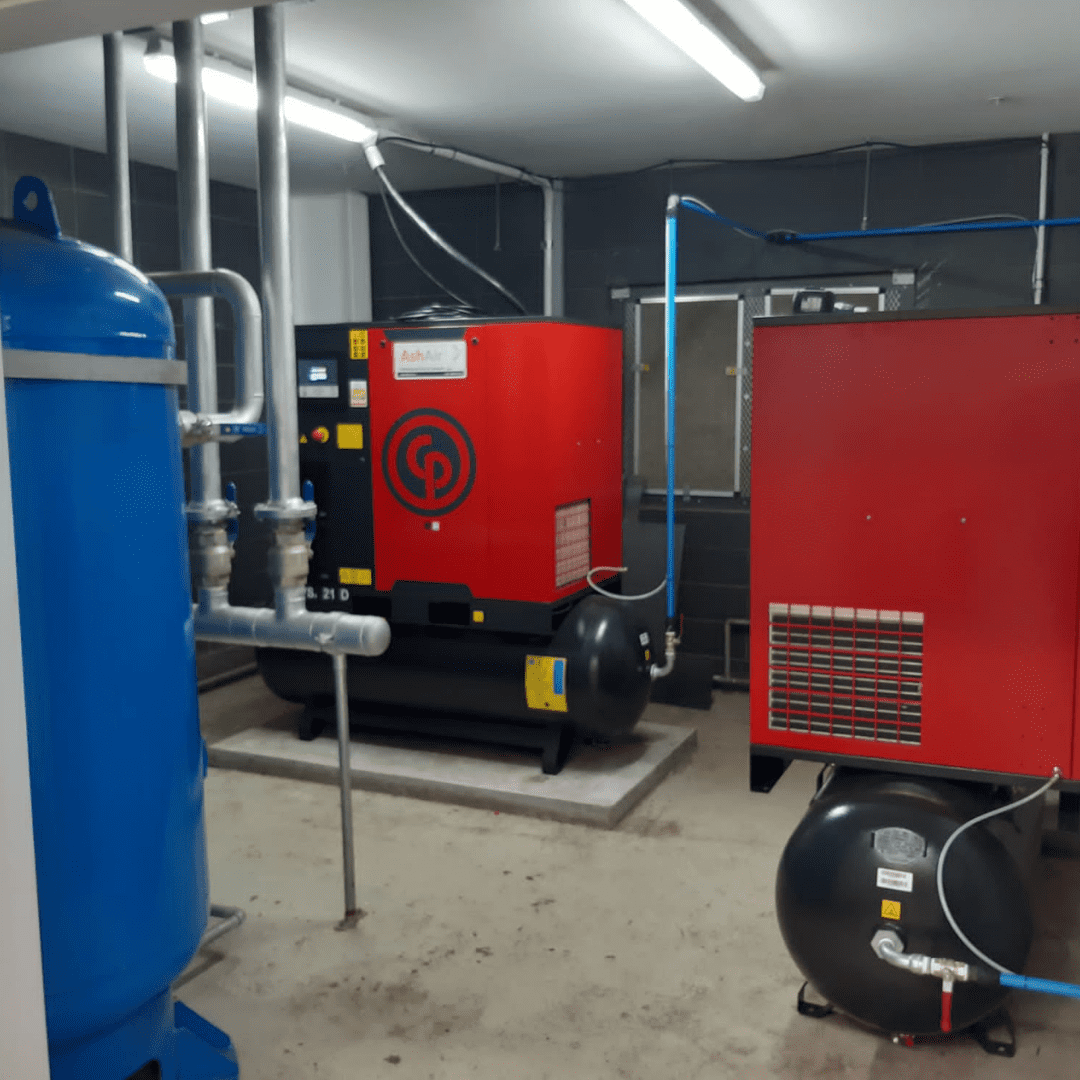

We get it, buying an air compressor is a big financial decision. And now we are suggesting that you need two air compressors, not just one. Ask yourself one question- Can your business still run if your air compressor goes down? Most likely, your answer is "no". If the compressor is shut off, what happens to the production? Do your people stop working? Can you not paint cars anymore? Can you not blast? If you've determined that your company cannot be without air at any time, then we highly recommend redundancy for your business.

‘Redundancy’ is a

term often used in the air compressor world. The word redundancy means that a second compressor is operating in parallel with the primary

compressor and both are sharing the demand. Should the primary unit fail, the second unit takes the full service. This ensures your

operation is never without compressed air.

‘Redundancy’ is a

term often used in the air compressor world. The word redundancy means that a second compressor is operating in parallel with the primary

compressor and both are sharing the demand. Should the primary unit fail, the second unit takes the full service. This ensures your

operation is never without compressed air.

If you're in a

business that has large compressed air requirements, a redundant system may service your business well. For such operations, having air

available at all times justifies the cost of multiple compressed-air systems to avoid costly line stoppages or shutdowns. Every air

compressor requires routine maintenance and upkeep to keep your machine running at its' optimal efficiency. Performing maintenance on your

air compressor will require your compressor to be shut off.

If you're in a

business that has large compressed air requirements, a redundant system may service your business well. For such operations, having air

available at all times justifies the cost of multiple compressed-air systems to avoid costly line stoppages or shutdowns. Every air

compressor requires routine maintenance and upkeep to keep your machine running at its' optimal efficiency. Performing maintenance on your

air compressor will require your compressor to be shut off.

Thank you to CP Compressors https://compressors.cp.com for providing this referal article and video.

Do you have an idea for our #expertcorner? Let

us know!

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a reputation for quality and reliability.We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, Alup, Pneumatech, and Quincy compressors are used extensively around the world in industries ranging from oil and gas to food, automotive and farming, and we bring you these world class compressors here in the land of the long white cloud.Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported by a 13 locations nationwide, Ash Air offers one of the widest selections of compressed air equipment and parts available today in New Zealand.

With Ash Air compressors, you can count on reliability and high performance for even the most demanding applications. We focus our efforts on the following:

Talk to the team today:

Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Maintenance budget: 8 factors to consider

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for maintenance can have potentially disastrous consequences. Read More…

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause complete dryer failure. Read More…