Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

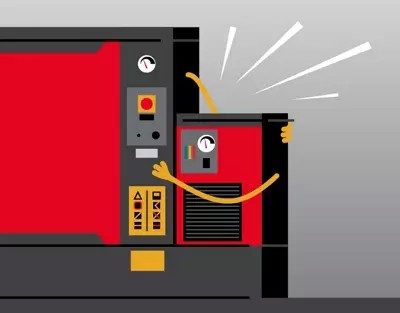

When speaking of air compressors, compressed air treatment is a process that dehumidifies and cleans air before entering the compressor. Most commonly, this process involves air filters and an air dryer. An effective compressed air treatment system lowers the “dew point” of the air and takes out particles that may negatively harm the air compressor.

Protecting

your investment is a smart decision with your compressed air system. Not only does compressed air treatment allow your system to run more

efficiently, but it also prolongs the life of the system by reducing rust and corrosion that can be caused by wet, dirty air. Because the

air being used by the air compressor is clean, it can run faster and doesn’t contain particles that can corrode the compressor over time.

Also, air that has undergone compressed air treatment is dry, meaning it does not promote the growth of rust like wet or humid air does.

Protecting

your investment is a smart decision with your compressed air system. Not only does compressed air treatment allow your system to run more

efficiently, but it also prolongs the life of the system by reducing rust and corrosion that can be caused by wet, dirty air. Because the

air being used by the air compressor is clean, it can run faster and doesn’t contain particles that can corrode the compressor over time.

Also, air that has undergone compressed air treatment is dry, meaning it does not promote the growth of rust like wet or humid air does.

Explore the list below of different air treatment solutions. In-Line Filters: primarily to remove

rust, scale, dirt, and other solid particles. Particulate filters are very versatile and can be used with either lubricated or

non-lubricated compressors. Often used to filter before and after the air enters & exits the compressor. Dryer:

Removes moisture from compressed air. Available in different types based on your application and needs. Air/Oil separator:

A device in the compressor that separates oil from the air/oil mixture compressed in the air-end. Condensate Drains:

Collect and discharge liquids from after-coolers, separators, receivers, dryers, filters, and drip legs.

Do you have an idea for our #expertcorner? Let

us know!

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a reputation for quality and reliability.We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, Alup, Pneumatech, and Quincy compressors are used extensively around the world in industries ranging from oil and gas to food, automotive and farming, and we bring you these world class compressors here in the land of the long white cloud.Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported by a 13 locations nationwide, Ash Air offers one of the widest selections of compressed air equipment and parts available today in New Zealand.

With Ash Air compressors, you can count on reliability and high performance for even the most demanding applications. We focus our efforts on the following:

Talk to the team today:

Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Maintenance budget: 8 factors to consider

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for maintenance can have potentially disastrous consequences. Read More…

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause complete dryer failure. Read More…