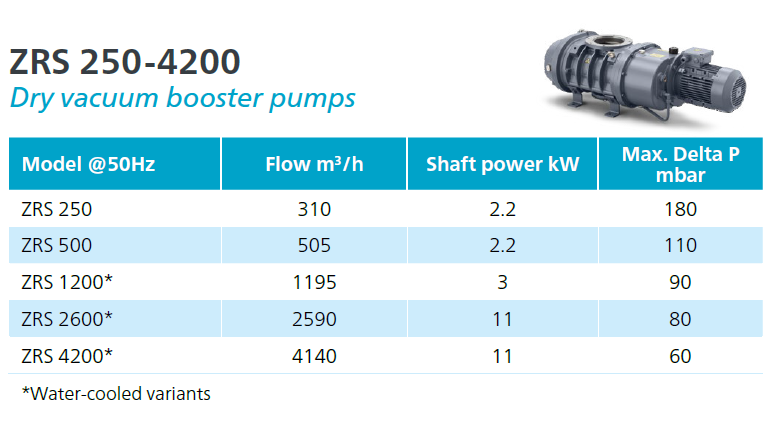

Atlas Copco ZRS 250-4200 Series

- Overview

ZRS 250-4200 Series from Atlas Copco

The ZRS mechanical booster pumps, based on the simple roots principle, remains the favourite pump for applications where high pumping speeds

are required for pressures in the region of 0.01 to 50 mbar. This pump must always be backed by another pump, which can deliver against a

high-pressure differential to atmospheric pressure. Operating at relatively low pressures, the mechanical booster pump is not exposed to the

same concentrations of corrosive process media as is the backing pump, which makes it highly reliable.

The ZRS Mechanical Booster pump is ideally suited for:

|

|

|

|

|

|

|

|

|

ZRS booster pumps have a unique and patented hydrokinetic fluid drive, which couples the motor to the pumping mechanism. No pressure sensors, by-pass lines or valves

The hydrokinetic drive allows the booster pump to be started at the same time as the backing pump as it prevents motor overload, assisting the pumping process from the start of pump-down

The hydrokinetic drive automatically varies the rotational speed of the pump, protecting the motor from overload and preventing over-heating. This allows the pump to operate with high-pressure differentials

Save money on installation and operation as capital costs are reduced because you do not need valves, by-pass lines and pressure switches

ZRS series - Designed to boost your production

• Suitable for applications where high pumping speeds are required in the pressure region of 0.01 to 50 mbar/0.0075 to 37.5 Torr.

• Operating at relatively low pressures makes it highly reliable.

• The ZRS pumps have a high quality, oil-free pumping mechanism. This offers:

• Quiet, vibration free operation.

• Rugged and corrosion resistant.

• Advanced shaft-seal technology with no oil contamination of the process chamber.

• The proven shaft-seal arrangement ensures that no oil enters the pumping stator, and the absence of internal and external by-pass lines and valves which may corrode or stick minimizes maintenance requirements.

• The design of the shaft seals is optimized to ensure that no lubricants can migrate into the pumping mechanism. This maintains booster pump performance in applications which demand the highest standard of cleanliness. In addition, this prevents the build-up of trapped particles on the rotor lobes and end-faces which have very close tolerances.

• The dynamically balanced rotors and precision ground gears contribute to the smooth, quiet operation of the pumps, as demanded by manufacturers of advanced technology equipment.

.png)

.jpg)