.jpg)

.jpg)

Atlas Copco GVS A Single Stage Oil Sealed Rotary Vane Vacuum Pump | 16 - 630 A

- Overview

Oil-sealed rotary vane pumps - GVS 16-630 A series

The GVS 16-630 A series operates according to the proven oil-sealed rotary vane principle that has been successfully used for many years in all general vacuum applications of industry packed with innovative features that ensure the highest possible performance at the lowest possible lifecycle cost.

The engine of any central vacuum system is the vacuum pump. Variable demand from your process often leads to frequent start-stops. These can

in turn lead to mechanical and electrical motor problems such as overheating, fan breakage, oil degradation and vane delamination.

Traditionally, the way to overcome these problems is to use a wide pressure band to limit the number of stop-starts. Unfortunately this is

not a cost-effective solution. A much better solution is to use a Variable Speed Drive (VSD). The vacuum pump with a VSD only delivers what

is required.

The GHS VSD⁺ series vacuum pumps are ideal for a range of applications in plastics, glass, bottling, canning, wood, packaging, printing and

paper, meat packaging and many more.

The built-in gas ballast valve is fitted as standard to assist in water vapor handling capability. Other functions include the lubricant retention and return mechanism which means that these machines are suitable for continuous operation between atmospheric pressure and their ultimate pressure.

separation to minimize oil vapors in the exhaust gas. The inlet non-return valve protects the vacuum pump against counter rotation in the event of stopping without venting, including back sucking of oil.

Proven oil-sealed rotary vane technology that includes overpressure oil system, installed oil mist filtering and all the options and accessories needed for general rough vacuum applications.

The GVS 16-630 A series has been successfully used for many years in all general industrial vacuum applications. It is robust and highly regarded product with reliable technology and design.

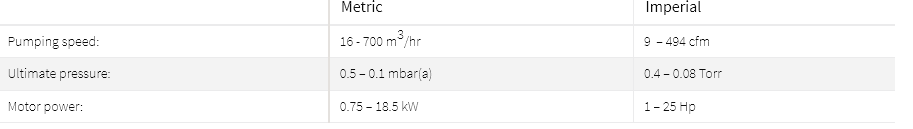

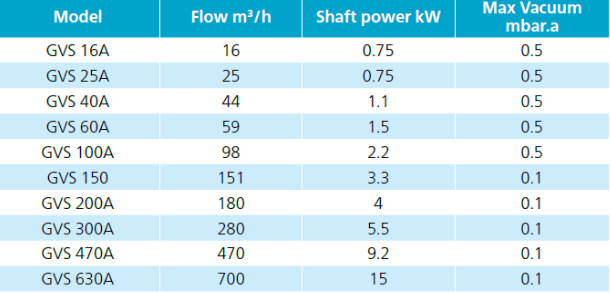

Technical Specifications

.

The GHS VSD⁺ series have shown a significantly better performance against traditional fixed speed technologies; potentially saving 50%* or

more in energy costs.

*In most applications compared to traditional fixed speed vacuum technologies based on measurement with our Vbox energy audit tool.

GVS A series - Robust oil-sealed rotary vane vacuum pumps

The GVS 16-630 A range are single-stage, oil sealed and air-cooled direct driven rotary vane vacuum pumps. Easy to install due to compact, space-saving design they offer a high reliability through a rugged design and optimal oil retention at all operating pressures

Ideal for all your vacuum needs

Providing highly efficient vacuum pumping performance, the GVS 16-630 A series is ideal for critical applications in packaging, woodworking, rubber, plastics, electronics, paper & printing, material handling and other exacting industries. Moreover, with ten models offering pumping speeds of between 16 and 840 m3/h (at 60 Hz), you will definitely find the right model for your specific application.

.jpg)

The GVS 16-630 A is ideally suited for:

|

|

|

|

|

|

|

|

|

The GVS VSD⁺ series is a robust and highly regarded range of vacuum pumps with a technologically advanced marketleading design. GVS VSD⁺

operates according to the proven oil-sealed rotary vane principle that has been successfully used for many years in all general vacuum

applications of the industry.

GVS 80-400 VSD⁺ is a range of compact direct-driven rotary vane vacuum pumps that are single stage, oil sealed, air cooled and have the

VSD⁺ inverter-drive technology built in. The VSD drive located on top of the pump ensures pressure setpoint control. Control and

monitoring are possible with the Atlas Copco VSD⁺ app – available for Android and iOS devices. With a Bluetooth connection, the app

offers you live visualizations of the actual performance of the pump. Reliable vane technology with added intelligence and connectivity

Reliable vane technology with added intelligence and connectivity

.png)