Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Compressed

air is always contaminated

Compressed

air is always contaminated

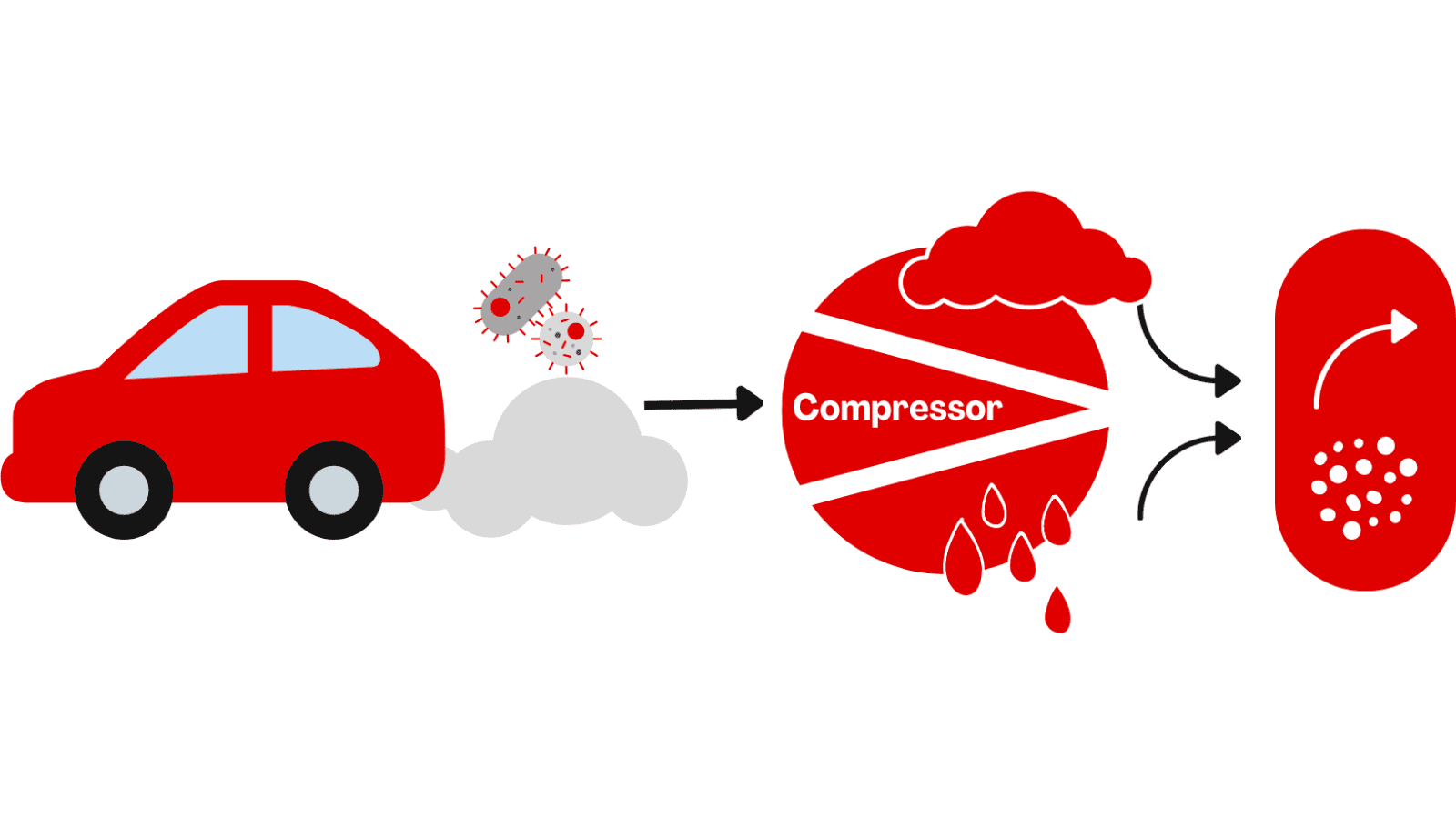

• Liquid oil - oil aerosols - oil vapor

• Dirt - microorganisms - pipescale

• Trace gases: carbon monoxide, sulfur dioxide, nitrous oxide

Added by the compressor installation through oil-lubricated compressors (oil), adsorption dryers and activated carbon filters (dirt), piping

network, and vessels (pipescale)

Trash in, trash out: oil vapors from car exhausts and industrial processes, atmospheric dirt, and microorganisms get sucked in by the

compressor. As with water, their concentration – and thus importance – increases significantly after compression.

• Damaged production equipment, leading to inefficiencies and increased costs

• Air pollution, creating unhealthy work environments

• Pollution of the condensate

• Coalescing filters for oil aerosols/particles

• Oil vapor filters

• Dust filters

• Oil-water separators

We offer AIRnet Piping Solutions!

AIRnet is a fast, easy and reliable piping system, designed for compressed air, vacuum, and other inert gas applications from the source to the point of use with the lowest total cost of ownership.

Ash Air offers you a comprehensive line-up of innovative filter solutions to meet your specific needs. Our filtration solutions are engineered to provide the best air quality. For general applications, we provide oil coalescing, particulate and oil vapour filters in a wide range of flows and pressures.

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a reputation for quality and reliability.We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, Alup, Pneumatech, and Quincy compressors are used extensively around the world in industries ranging from oil and gas to food, automotive and farming, and we bring you these world class compressors here in the land of the long white cloud.Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported by a 13 locations nationwide, Ash Air offers one of the widest selections of compressed air equipment and parts available today in New Zealand.

With Ash Air compressors, you can count on reliability and high performance for even the most demanding applications. We focus our efforts on the following:

Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Maintenance budget: 8 factors to consider

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for maintenance can have potentially disastrous consequences. Read More…

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause complete dryer failure. Read More…

Why Replace CO2 with Nitrogen in your Brewery

Using nitrogen is not about fully replacing CO2, but it can reduce their consumption of CO2 by close to 70%. Using nitrogen is about sustainability. Creating your own nitrogen is easy and will reduce the use of a greenhouse gas, which is better for the environment. It will also save you money as early as month one adding that savings to your bottom line. Read More…

What do I need to know about ICONS?

ICONS: Intelligent Connectivity System: The insight into your compressed air system, wherever you are. Learn More about ICONS in this article here! Read More…

A question that is occasionally asked by our customers to Ash Air is 'what is the cost of compressed air?' This article looks at the product costs involved with compressed air, as well as minimising the energy cost of compressors and cost allocation. When looking at these factors, we need to realise what causes dropped efficiency of your compressor, leading to increased costs of compressed air. Read More…

How to avoid falling objects when working at heights

You may have great fall protection measures in place to keep employees safe when working at height, but what about their co-workers below? Dropped tools and other falling objects are a major hazard – and one that isn’t always fully addressed. Read More…

Providing a safe working environment for operators is essential, especially when using pneumatic tools and compressed air. If there is a failure in the air network and the hose is not adequately clamped, the resulting whiplash could be devastating. Failure to follow best practice can result in injuries, associated production downtime and decreased productivity. Read More…