Chicago Pneumatic CPVSd 40 Oil Injected Screw Compressor with Variable Speed Drive (VSD)

- Overview

- Specifications

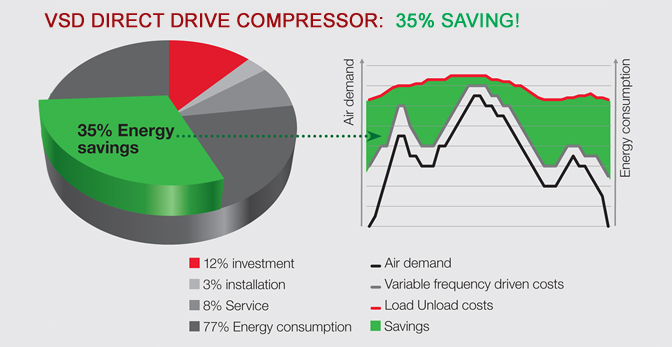

Advanced VSD direct drive in a perfect all-in-one solution

Cleverly built by joining together gearbox technology and Variable Speed Drive innovation, the CPVSd 40 and CPVSd 50 are perfect for applications that demand high energy efficiency, rebustness, and reliability. Up to 35% of energy consumption can be saved through a combination of advanced elements, compared to a fixed speed machine of the same size. This series is a brilliant choice for modern engineering and manufacturing facilities. Equipped with ES4000 ADVANCED controllers, the machine operates to its maximum efficiency when you have a full control of your compressed air system. Apart from being installed as a stand-alone unit by itself, the CPVSd 40 and CPVSd 50 can also be networked to another fixed speed (load-unload) compressor acting as a regulator for the whole site, increasing the total efficiency to the next level.

Benefits of Variable Speed Drive

- High energy efficiency with an intelligent inverter and sensors

- Smooth start - no peak current penalties on mechanical parts at start-ups (prolong components' life)

- Reduced system pressure = Reduced energy consumption

- Reduced system pressure = Minimised air leakages

- Complete with 270L receiver and dryer

- Highly efficient C55 Star Air-end

- VSD + Direct drive - High energy efficiency

- Low costs of ownership

- Quiet: 70 dB(A)

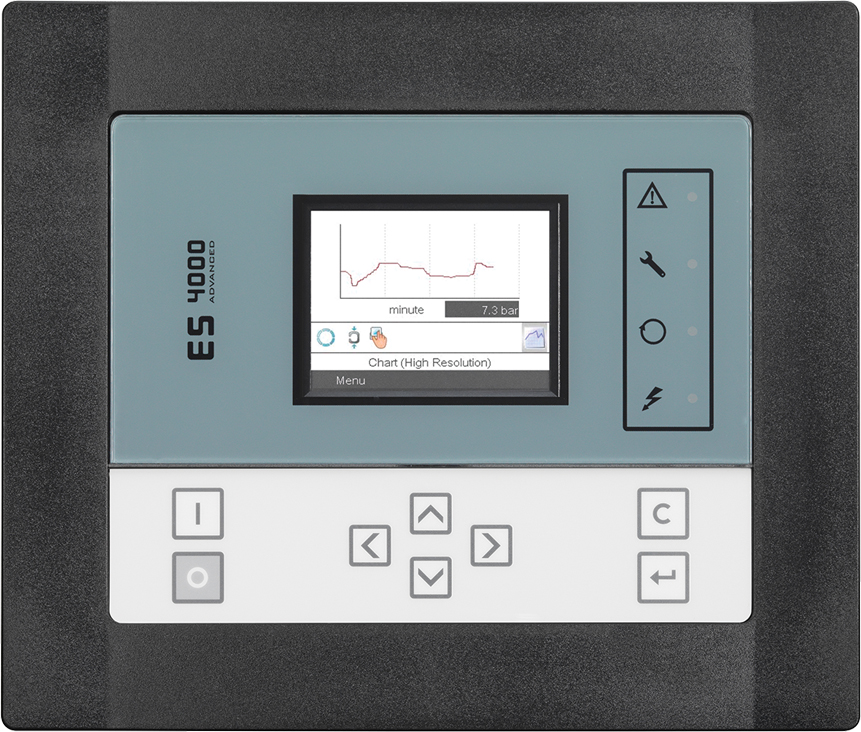

- ES4000 ADVANCED graphic controller

Key benefits

- Highly efficient element ensures low energy consumption and long term performance

- Highly efficient belt transmission reducing energy consumption

- Direct driven transmission for further energy saving (CPVSd)

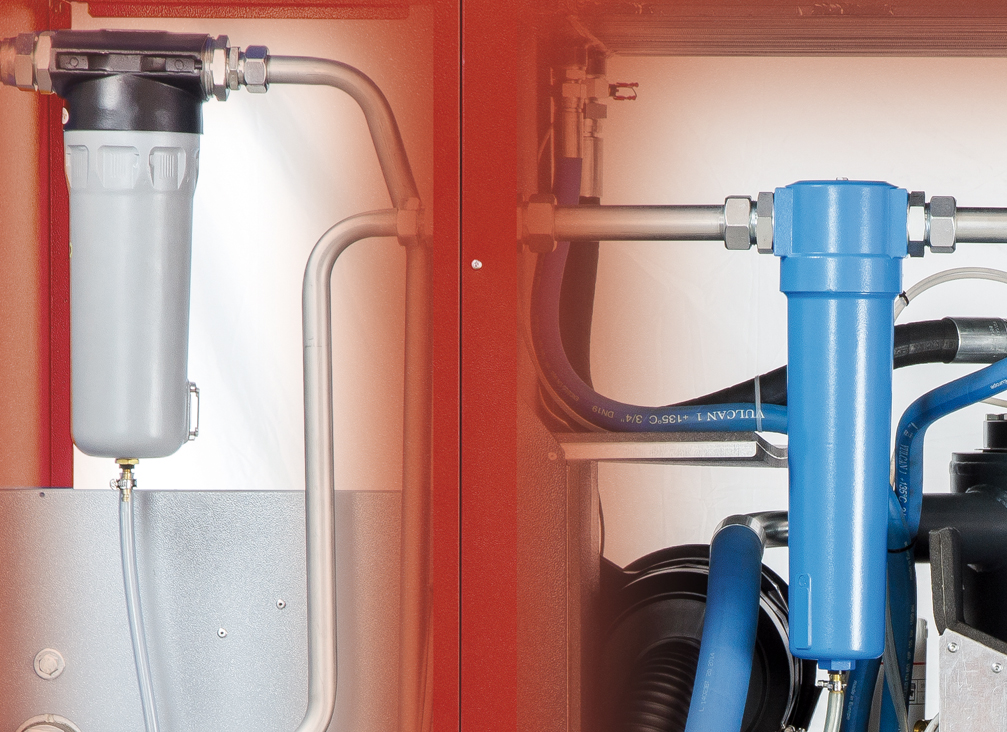

- Protects your air network against rust and corrosion thanks to integrated solutions (dryer, air filter,…

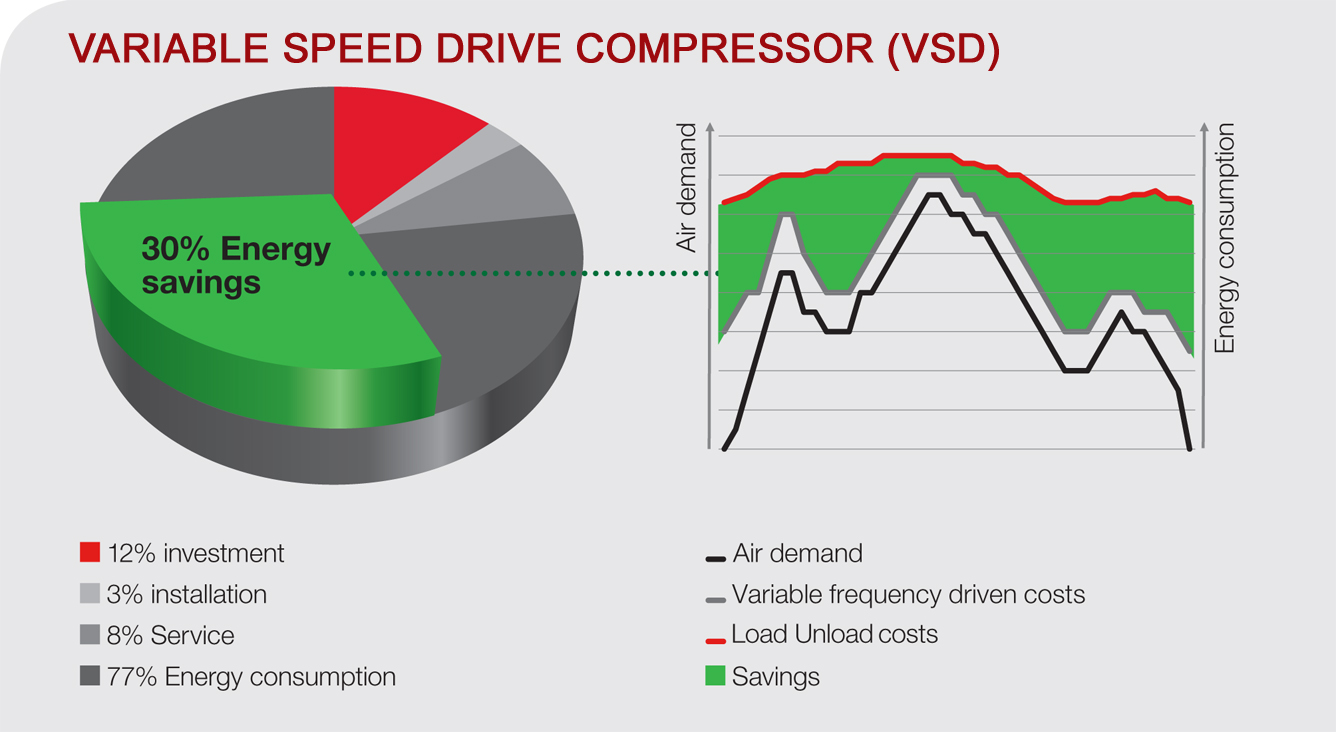

- Inverter technology perfectly matching the air flow with the air demand saving energy costs up to 30%

- User-friendly controller for full control

Features

Cost energy reduction and sustainability

Up to 35% of energy savings and an average cut of 25% in the compressor lifecycle cost thanks to IE3 motors or Variable Speed technology, combined with the direct driven transmission design. Optimal efficiency, lubrication and cooling and long service intervals

Customisable with wide range of options

This rotary screw compressor range is available in Variable Speed direct –driven and Fixed speed gear driven versions. Customable options include energy recovery to reduce energy bill and canopy heaters for low temperature installation

Simple installation

Compact and all-in-one system, thanks to the oversized integrated dryers. No special foundation needed

Built to last

ES-4000

Easy access for servicing

All service components are located at the front of the machine for top accessibility.

VSD Energy Savings

Energy Efficiency

Variable Speed Drive (VSD) compressors can save up to 35% of system energy costs.

More than 80% of a compressor’s lifecycle cost comes from the consumption of energy. Therefore we focus on reducing your energy bill by adapting your compressors’ output with the demanded air input.

How it works

Operations have a fluctuating demand for air, so our VSD technology for compressors makes sure that you and your business get the required air at the required time.

This makes sure that your compressor is not using more energy than needed, effectively decreasing your energy consumption, and increasing your energy efficiency.

More than 80% of a compressor’s lifecycle cost comes from the consumption of energy.

Therefore we focus on reducing your energy bill by adapting your compressors’ output with the demanded air input.

On average we save your company 35% of the energy cost usually related to compressor costs. This gives you a competitive advantage.

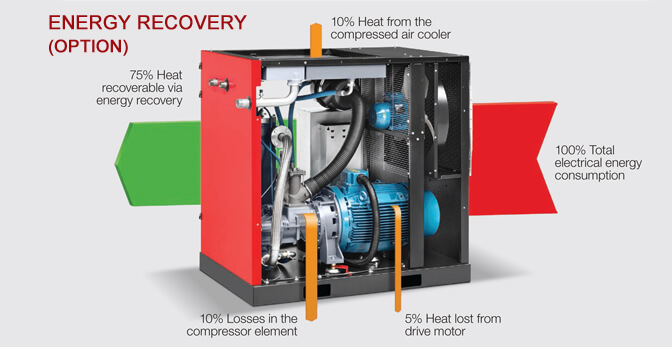

Energy Recovery

The energy recovery option can capture heat and recover up to 75% of energy loss.When looking at the typical carbon footprint of an air compressor - from the design phase right through to the equipment’s recycling - the energy consumed in its use accounts for 99% of CO2 emissions.

As energy consumption also typically represents over 80% of a compressor’s lifecycle cost, energy savings in compressed air systems will have a significant impact towards preserving not only the environment but also your bottom line.

While compressed air systems in general account for about 10% of total industrial electricity consumption, this can amount to as much as 40% of the electricity bill for certain plants.

How does compressor heat recovery work?

Up to 94% of the electrical energy is converted into compression heat. Without energy recovery, this heat is lost into the atmosphere via the cooling system and radiation.

You can use hot water recovered from the compressed air system for sanitary purposes and space heating. But it is particularly suitable for process applications. Using the hot water as boiler pre-feed or directly in processes requiring 70 to 90°C can save you costly energy sources such as natural gas and heating oil.