Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Mention diamonds and most people will associate that with the jewelry sector. They will also have in mind that such gems are to be found in mines and sometimes won under severe conditions (“blood diamonds”). For such reasons, the industry already investigated in the 1950s how to produce synthetic diamonds.

Today,

there are several processes available to create artificial diamonds. Not only for jewelry where even experts are challenged to

differentiate a natural diamond from an artificial, but also for the much larger market for diamonds in the industrial sector.

Today,

there are several processes available to create artificial diamonds. Not only for jewelry where even experts are challenged to

differentiate a natural diamond from an artificial, but also for the much larger market for diamonds in the industrial sector.

The key properties of synthetic diamonds that make them so interesting for the industrial sector are:

Some typical industrial application examples are machining and cutting tools, window material for transmitting infrared and microwave radiation, and heat sinks for lasers and transistors. Synthetic diamonds are also the base material for semiconductor wafers and Qubits for quantum computing.

Traditionally diamonds were naturally formed billions of years ago in the earth’s crust by carbon atoms being exposed to intense heat and pressure. However, due to technical advances, a new source of synthetically grown diamonds was created. This market can be divided into 2 main manufacturing methods:

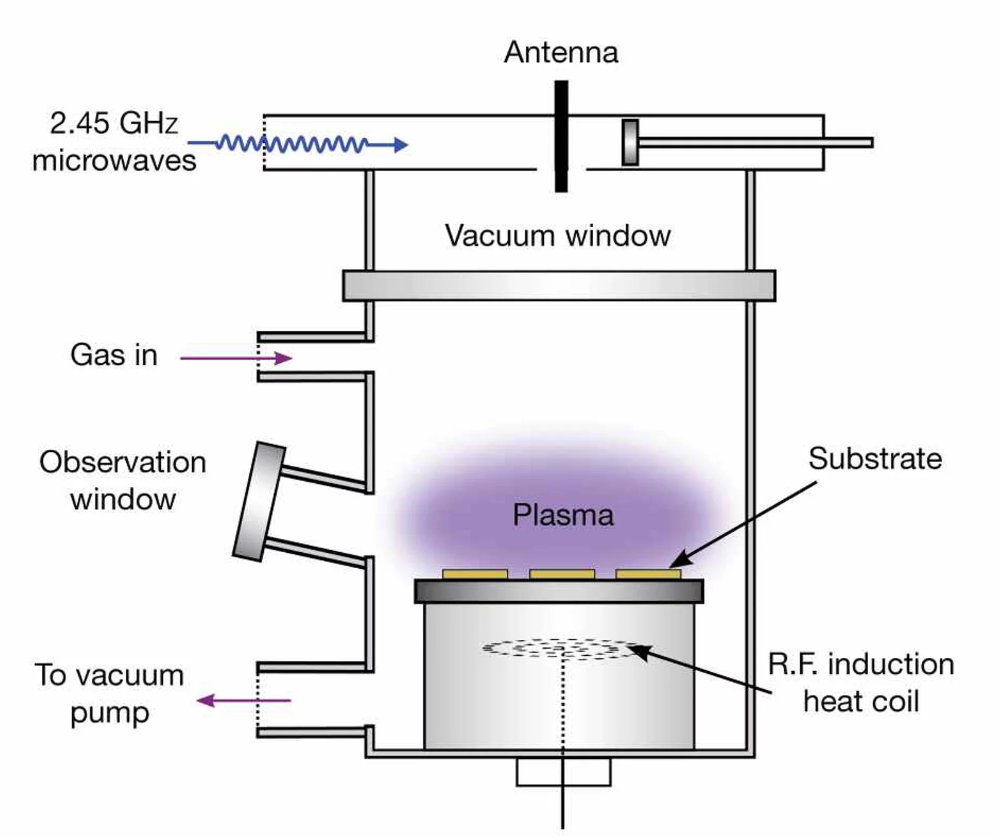

Due to its small footprint and excellent process controls, the MPCVD growing process has gained in popularity. One important part of the MPCVD process is the creation of and maintaining optimal vacuum conditions inside a growth chamber. A typical growth chamber setup looks as below:

Synthetic diamond-making process. Source: NNE, 2019

The typical process steps are the following:

Nowadays, oil-sealed rotary vane pumps are typically used in the MPCVD process. This is because these pumps are very well suited to achieve low conditioning pressure but also because they are mainly designed for continuous operation at fine vacuum. Additionally, these pumps face poor lubrication, overheating, or high oil loss when operating for days in the rough pressure phase required by this process.

The oil lubrication of these vacuum pumps is secured by a built-in oil pump, which also enables a uniform oil distribution at rough pressure operation, whereas standard pumps without such oil pumps could fail.

Our range of rotary vane pumps is designed for operation at rough pressure and provides a perfect solution for the diverse pressure requirements of this growing process:

The Ash Air range of rotary claw vacuum pumps is the best alternative to rotary vane pumps. A vacuum claw pump is virtually zero maintenance and compared to rotary vane pumps can work at vacuum levels of 400 to 1000 mbar without overheating. Rotary claw vacuum pumps are the best choice for CNC guided wood routers.

The Ash Air range of humble liquid ring pumps is still the most reliable form of large volume vacuum generation available today. These liquid ring pumps are simple to use and very reliable, and the best option when sucked air contains a large amount of saturated gas.

Dry and oil-sealed vane vacuum pumps are robust, affordable and easy in maintenance. You can use DVP vane pumps for wide range of application, for skin packaging, holding, lifting, thermoforming.

We have a quality range of oil-sealed screw pumps for sale that are energy efficient and have low life-cycle costs.

We have a great range of new and hire blowers from single stage ring blower through to large lobe blowers, and we also stock the service parts for common blowers across many brands.

Our roots blowers, side channel blowers are built to last, and are backed up by our promise of excellent customer service to keep your business performing well day in and day out.

With hundreds of years of combined experience and a broad product range, Ash Air is a great partner for your vacuum pump operations. From rotary vane pumps to screw pumps and accessories, we have a large variety of products. We also have a dedicated applications team ready to calculate the ideal pump configuration. With a global support organization, we can support your manufacturing operations wherever they may be located in New Zealand.

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a

reputation for quality and reliability.We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, Alup, Pneumatech, and Quincy compressors are used extensively around the world in industries

ranging from oil and gas to food, automotive and farming, and we bring you these world class compressors here in the land of the long white

cloud.Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported by a 13 locations

nationwide, Ash Air offers one of the widest selections of compressed air equipment and parts available today in New Zealand.

With Ash Air compressors, you can count on reliability and high performance for even the most demanding applications. We focus our

efforts on the following:

Talk to the team today:

Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider.

Read More…

Maintenance budget: 8 factors to consider

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire

lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for

maintenance can have potentially disastrous consequences.

Read More…

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause

complete dryer failure.

Read More…

Do you have an idea for our #expertcorner? Let

us know!

Who we are and how Ash Air can help your business!

Reliability and Efficiency

Read more from our #expertcorner