Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

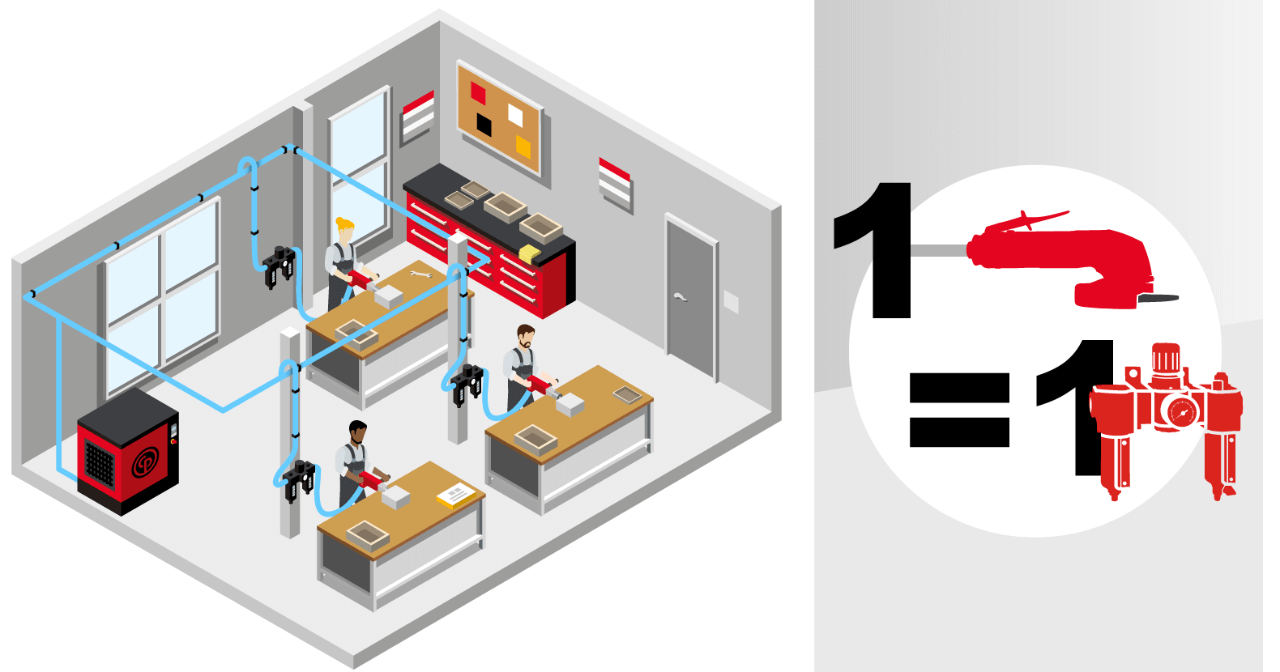

FRLs – Filters, Regulators and Lubricators – guarantee the efficiency and durability of pneumatic tools. Including an FRL in your air system is vital to running an efficient air line set-up and key to achieving a good return on investment. Adding an FRL in close proximity to the power tool will ensure the required airflow pressure, as well as good air quality by reducing the risk of moisture and dust in the air line. The FRL also helps maintain your air line by providing lubrication.

Dust in an engine could block the air flow and reduce the power of the tool leading to increased maintenance costs as well as high air consumption. Any dirt and rust could also damage the engine resulting in power loss and early wear. This increases tool repair costs and the risk of incident during production.

This is important because if the pressure is lower than the one recommended by the manufacturer, the tool can’t reach its performance level and the profitability is decreasing. If the pressure is too high, the tool wears out early. It could also breakdown leading to operator injury and a risk of damage to the application.

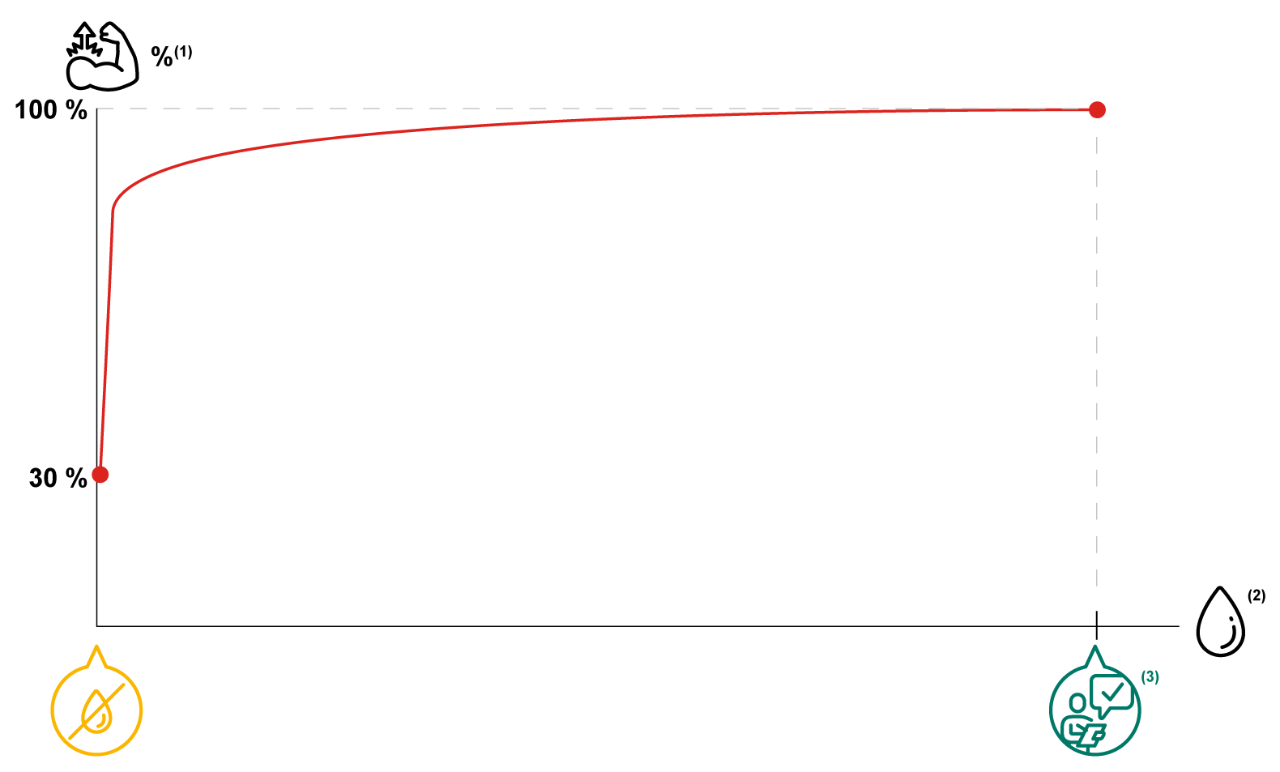

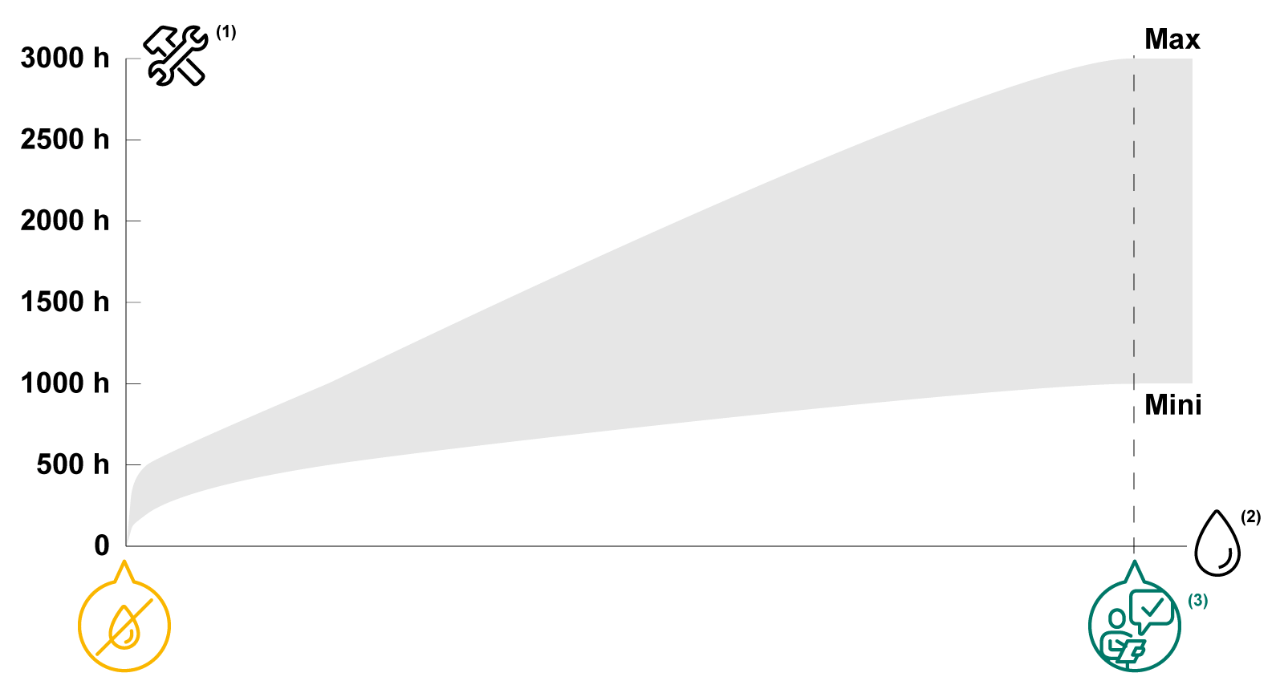

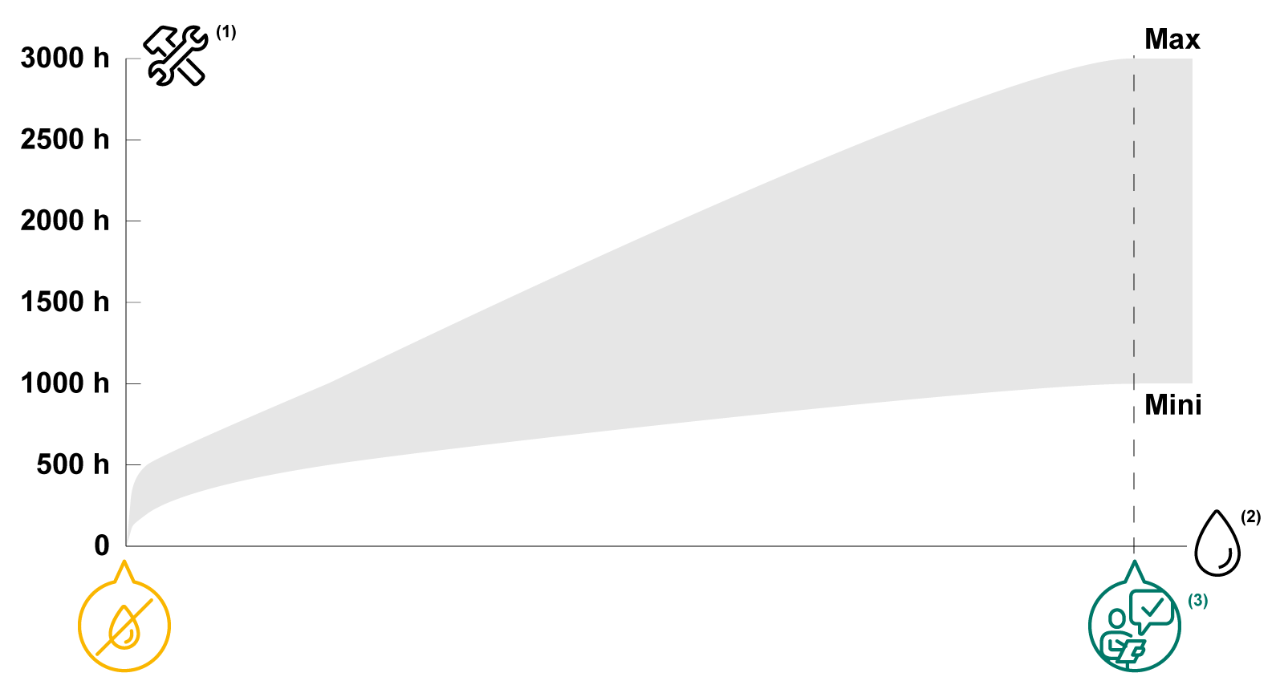

Without lubrication a tool wears out and will stop reaching its maximum level of performance. This in turn leads to a loss of productivity and increased maintenance costs. The graphics below illustrate the durability and the service life of the tool’s air motor with and without lubrication maintenance:

Achieve optimum performance of your tool’s air motor with good lubrication:

Estimated figures based on laboratory tests carried out on pneumatic motors.

(1) Tool’s motor power output

(2) Oil quantity

(3) Tool manufacturer recommendations (available in operator/product manual)

Achieve optimum service life of your tool’s air motor with good air lubrication:

Estimated figures based on laboratory tests carried out on pneumatic motors.

(1) Tool’s motor power output

(2) Oil quantity

(3) Tool manufacturer recommendations (available in operator/product manual)

There are many different types of FRLs, and so when specifying an FRL there are 4 key considerations:

Important: Make sure you always check manufacturer recommendations.

Pneumatic tools are designed and specified to work at 90 PSI (6.3 bar) dynamic air pressure and with lubrication (find all information in the tools’ operator manuals available in the Chicago Pneumatic website). A higher pressure could affect the tools lifespan, and operator safety (excessive vibration, or abrasive over-speed and burst risk). We recommend using a gauge equipped FRL with every tool to adjust pressure.

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a reputation for quality and reliability.

We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, Alup, Pneumatech, and Quincy compressors are used extensively around the world in industries ranging from oil and gas to food, automotive and farming, and we bring you these world class compressors here in the land of the long white cloud.

Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported by a 13 locations nationwide, Ash Air offers one of the widest selections of compressed air equipment and parts available today in New Zealand.

With Ash Air compressors, you can count on reliability and high performance for even the most demanding applications. We focus our efforts on the following:

We offer a broad array of products, from world class compressor brands, including a full range of rotary and reciprocating air compressors from ½ to 200 horsepower. We serve the compressed air needs of many industries such as the following:

In our effort to prioritise the needs of our customers, we work hard to provide solutions. We continually introduce innovative products here at Ash Air to our Kiwi customers, so our end users can rely on us to meet evolving compressed air needs.

We offer an extensive array of air compressor parts and services through our direct locations throughout New Zealand. Continued growth means our operations continue to operate on a national level.

In our effort to provide the best possible support, we offer the following remote monitoring, preventative maintenance, vacuum pump services and overhaul, compressor and pipework installations, hire fleet and leasing solutions, leak detection's and energy audits, and breakdown recovery and emergency air.

When considering new energy-efficient air compressors or an upgrade to more energy-efficient machinery, Ash Air can help you make the right choices for your business.

Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Maintenance budget: 8 factors to consider

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for maintenance can have potentially disastrous consequences. Read More…

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause complete dryer failure. Read More…

Why Replace CO2 with Nitrogen in your Brewery

Using nitrogen is not about fully replacing CO2, but it can reduce their consumption of CO2 by close to 70%. Using nitrogen is about sustainability. Creating your own nitrogen is easy and will reduce the use of a greenhouse gas, which is better for the environment. It will also save you money as early as month one adding that savings to your bottom line. Read More…

What do I need to know about ICONS?

ICONS: Intelligent Connectivity System: The insight into your compressed air system, wherever you are. Learn More about ICONS in this article here! Read More…

A question that is occasionally asked by our customers to Ash Air is 'what is the cost of compressed air?' This article looks at the product costs involved with compressed air, as well as minimising the energy cost of compressors and cost allocation. When looking at these factors, we need to realise what causes dropped efficiency of your compressor, leading to increased costs of compressed air. Read More…