Pneumatech PPNG 1-12 High Pressure Nitrogen Skids HE

- Overview

PPNG 1-12 High Pressure Nitrogen Skids HE

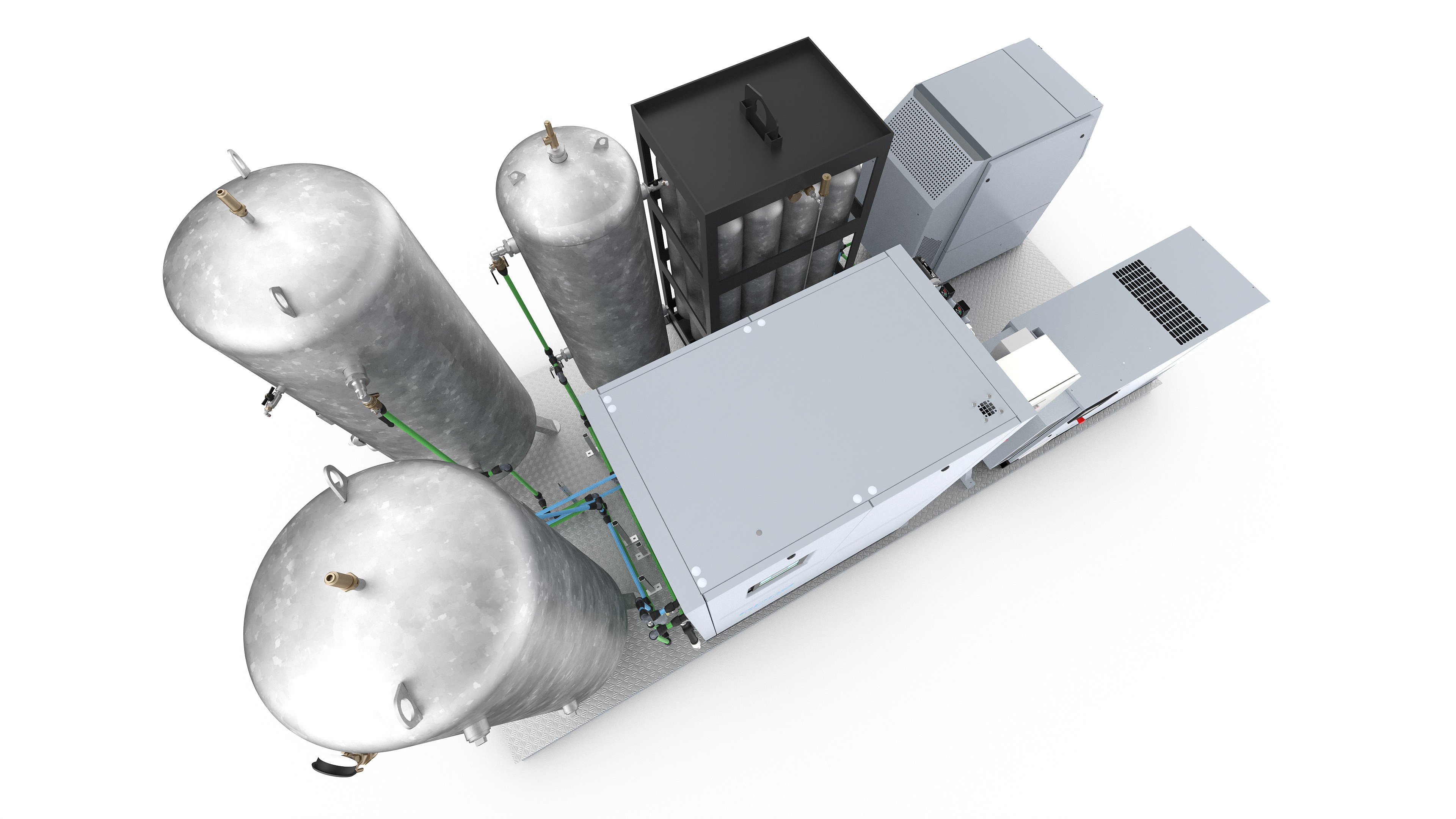

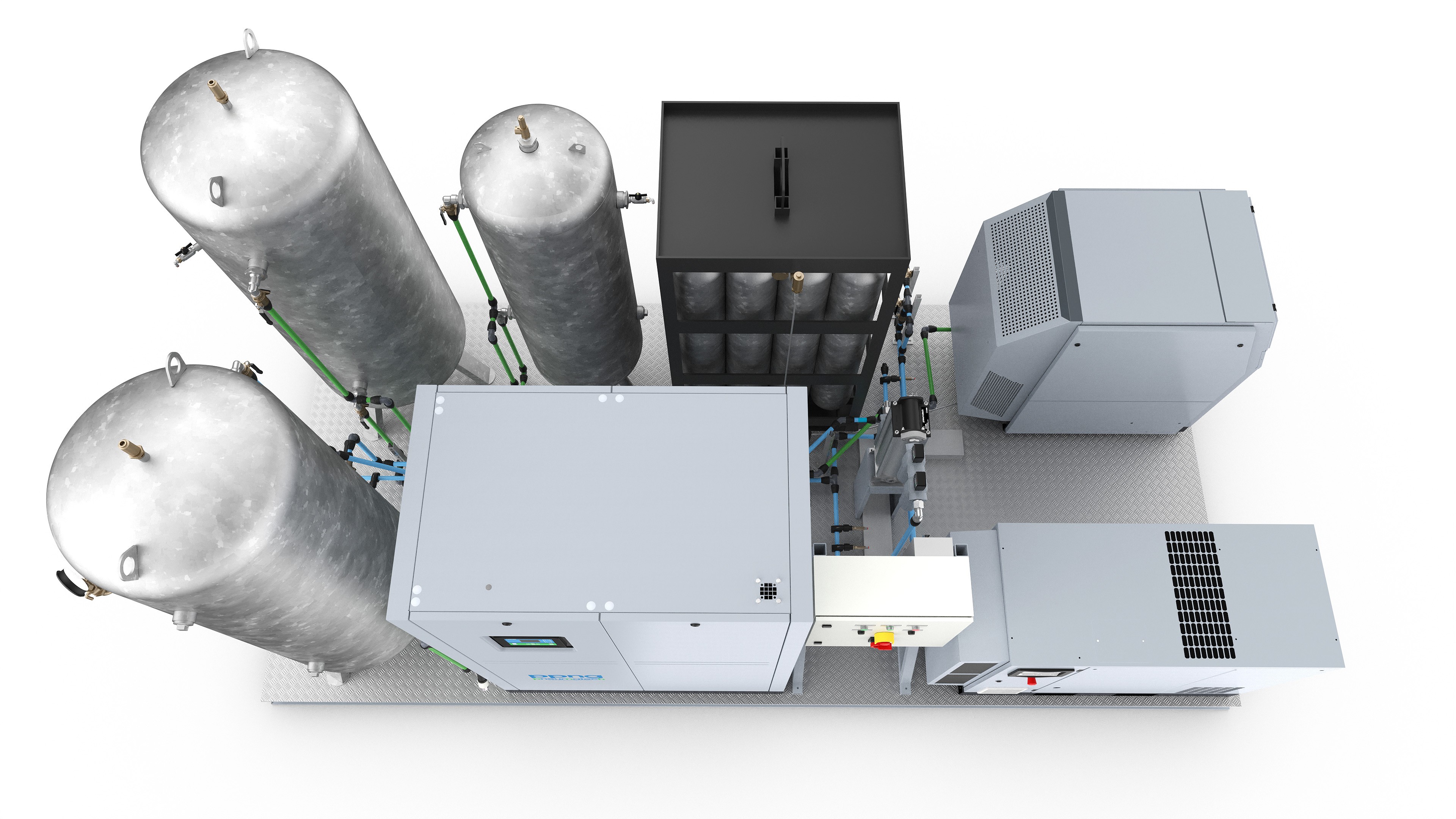

The PPNG skid HE is the all-in-one, plug-and-play nitrogen generation system that is ideal for laser cutting.

The PPNG skid HE is the complete on-site nitrogen generation system that gives you total control over your nitrogen supply and significant cost savings.

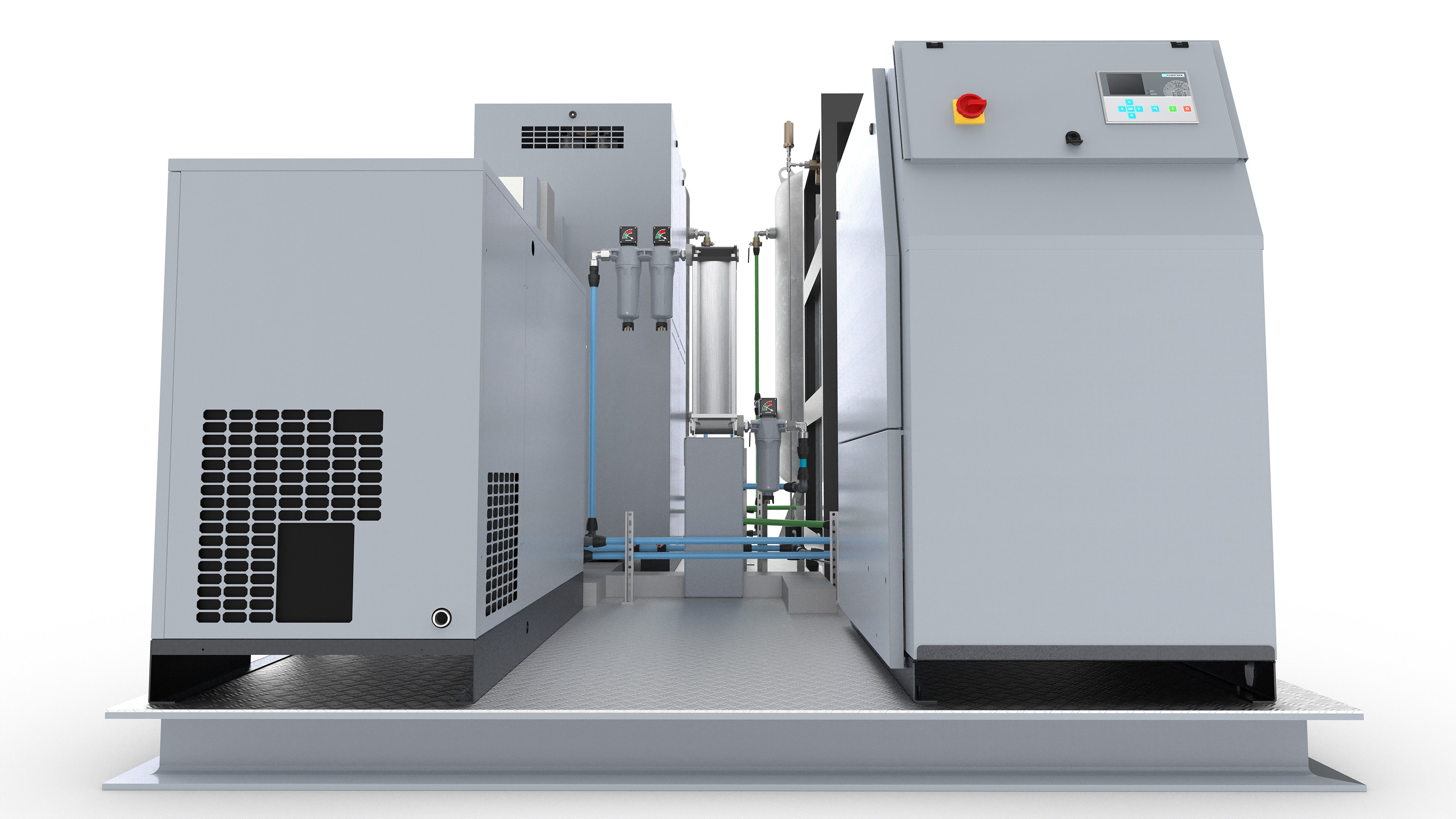

The compact and sturdy base frame contains a complete high-pressure nitrogen generation system: a VSD compressor, a high-pressure booster, a premium PSA nitrogen generator, and all necessary air and nitrogen storage and treatment.

All components are built and tested to deliver a completely turnkey solution with just one power supply and one nitrogen connection. In addition, you can optionally also use the skid to meet your compressed air needs.

To give you maximum flexibility, the PPNG skid HE comes in two versions: 40-bar for peak and on-demand nitrogen and 300-bar with cylinder storage. Each comes in different sizes and with a wide range of accessories to meet your specific needs.

The PPNG skid HE will also reduce your operational costs. Compared to other nitrogen packages, you save 30% on energy costs. That’s because efficiency is built-in in all the skid’s components, from the Variable Speed Drive compressor, the highly efficient booster, to the nitrogen generator with optimized PSA technology.

The PPNG skid HE is the preferred nitrogen solution for laser cutting and other high pressure applications that require high

uptime, purity, flow, and gas quality.

All-in-one/plug-and-play

- All-in-one nitrogen generation system

- Single power supply for the complete skid

- Forklift slots for easy lifting and moving

- PPNG HE nitrogen generator with energy savings at full and low load

Reduced energy costs

- 30% more efficient than other high-pressure N2 packages

- VSD compressor with integrated refrigerant dryer

- 40 or 300-bar booster sized to minimize power use

Guaranteed purity

- Purity selection up to 99.999%

- Automatic nitrogen pressure and purity regulation

- Zirconia sensors for reliable purity measurement

Reliability

- Several layers of filtration

- Protective features

- All components built and tested to work together optimally

PurelogicTM control & monitoring

- Self-protective monitoring of feed air quality

- Nitrogen flow, purity and pressure measurement and control

- Optional 24/7 ICONS remote monitoring

PPNGs nitrogen generator

- Guaranteed purity

- Outstanding air factors

- Energy saving control

- Optimal control and monitoring thanks to Purelogic™ controller

- Very quiet operation due to improved noise insulation

- Compact design, also thanks to integrated refrigerant dryer

4-stage filter train for guaranteed purity and reliability

- General-purpose and high-efficient oil-coalescing filters, activated carbon tower and high-efficient particle filter

- Guaranteed air quality of class 1:4:1 (according to ISO8573-1:2010) at the inlet of the nitrogen generator

Variable speed compressor with integrated refrigerant dryer

- Closely follow the air demand by automatic adjustment of the motor speed

- Direct driven transmission for outstanding energy efficiency and reliability

The PPNG high-pressure nitrogen skid

The ideal solution for laser cutting

Many companies that do laser cutting still purchase their nitrogen – even though generating your own gas on-site offers more advantages.

Here are just four:

- Greater cost-efficiency saves you money

- Eliminating bottle or liquid deliveries reduces your environmental footprint

- Take charge of your own nitrogen supply

- Less hassle by removing supply logistics

Creating exceptional partnerships throughout New Zealand - customer story

Discover the power of high-pressure nitrogen skids with Ash Air's Pneumatech PPNG NE nitrogen skid. The ultimate all-in-one solution, featuring a variable speed drive (VSD) compressor, high-pressure booster, premium PSA nitrogen generator, and comprehensive storage and treatment capabilities.

We talked to Cut Fold NZ about their Ash Air installed Pneumatech n2 skid, providing

high quality cutting and folding nationwide from their purpose built facility located in Te Awamutu. Cut Fold NZ offers high quality

cutting and folding throughout New Zealand.

"Buying a Nitrogen Skid through Ash Air means that we can run 24 hours a day without worrying about running out of Nitrogen! Ash

Air turned up to Cut Fold NZ, craned the [Nitrogen Skid] into place, and it has been working flawlessly. The Pneumatech Nitrogen Skid

currently produces between 99.995 % and 99.999% purity! Ash Air have been really good to deal with...easy, reliable, good honest

feedback, and simple to deal with. I highly recommend them".

Brian Edwards

Director,

Cut Fold NZ

| Technical specifications for PPNG 1-6 skid HE | ||||||

| Pneumatech Variant | PPNG Skid 1 HE | PPNG Skid 2 HE | PPNG Skid 3 HE | PPNG Skid 4 HE | PPNG Skid 5 HE | PPNG Skid 6 HE |

| N2 pressure - Nominal | 40 | 40 | 40 | 40 | 40 | 40 |

| N2 capacity - 99.95% | 8.9 | 14 | 21.6 | 31.5 | 36.9 | 73.8 |

| N2 capacity - 99.99% | 6.6 | 10.4 | 20.6 | 30.3 | 36.9 | 73.8 |

| N2 capacity - 99.999% | 4.1 | 6.3 | 13.6 | 20.4 | 27.2 | 49.7 |

| Compressor model | 8 kw | 11 kw | 15 kw | 22 kw | 31 kw | 45 kw |

| Inlet filtration | PMH G - C - VT - D | PMH G - C - VT - D | PMH G - C - VT - D | PMH G - C - VT - D | PMH G - C - VT - D | PMH G - C - VT - D |

| Air / N2 buffer vessels (L) | 500 | 500 | 1000 | 1000 | 1500 | 2000 |

| Nitrogen generator | PPNG12 HE | PPNG18 HE | PPNG37 HE | PPNG50 HE | PPNG68 HE | PPNG100 HE |

| Nitrogen LP storage | 1000 | 1000 | 1000 | 1500 | 1000 | 2000 |

| Nitrogen booster | 7.5 kw | 7.5 kw | 7.5 kw | 7.5 kw | 7.5 kw | 7.5 kw |

| HP filtration | 50 Barg G - C - V - D | 50 Barg G - C - V - D | 50 Barg G - C - V - D | 50 Barg G - C - V - D | 50 Barg G - C - V - D | 50 Barg G - C - V - D |

| HP storage | 45 Barg 500L | 45 Barg 500L | 45 Barg 1000L | 45 Barg 1000L | 45 Barg 1000L | 45 Barg 1000L |

| Technical specifications for PPNG 7-12 skid HE | ||||||

| Pneumatech Variant | PPNG Skid 7 HE | PPNG Skid 8 HE | PPNG Skid 9 HE | PPNG Skid 10 HE | PPNG Skid 11 HE | PPNG Skid 12 HE |

| N2 pressure - Nominal | 300 | 300 | 300 | 300 | 300 | 300 |

| N2 capacity - 99.95% | 9.9 | 14.9 | 24 | 36 | 38 | 80.4 |

| N2 capacity - 99.99% | 7.3 | 11.1 | 22.9 | 32.9 | 38 | 80.4 |

| N2 capacity - 99.999% | 4.5 | 6.9 | 15.1 | 22.4 | 29 | 55.2 |

| Compressor model | 8 kw | 8 kw | 15 kw | 19 kw | 22 kw | 45 kw |

| Inlet filtration | PMH G - C - VT - D | PMH G - C - VT - D | PMH G - C - VT - D | PMH G - C - VT - D | PMH G - C - VT - D |

PMH G - C - VT - D |

| Air / N2 buffer vessels (L) | 500 | 500 | 1000 | 1000 | 1500 | 2000 |

| Nitrogen generator | PPNG12 HE | PPNG18 HE | PPNG37 HE | PPNG50 HE | PPNG68 HE | PPNG100 HE |

| Nitrogen LP storage | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 |

| Nitrogen booster | 5.5 kw | 5.5 kw | 5.5 kw | 11 kw | 11 kw | 2x11 kw |

| HP filtration | HP V filter | HP V filter | HP V filter | HP V filter | HP V filter | HP V filter |

| HP storage | 12 x 50L X 300 Barg | 12 x 50L X 300 Barg | 12 x 50L X 300 Barg | 16 x 50L x 300 Barg | 16 x 50L x 300 Barg | 16 x 50L x 300 Barg |

Discover the benefits

High pressure nitrogen skid for on-site gas generation

1. Cost efficiency

Built with the latest technology, providing significant savings on energy costs. You enjoy a lower cost per unit of gas.

2. Sustainability

Designed with the highest efficiency equipment, a skid minimizes energy consumption. You also eliminate the transport emissions of gas

deliveries.

Our PPNG NE nitrogen skid provides an all-in-one solution

3. Reliable nitrogen supply

No need to count on external vendors. On-site generation provides complete control over supply.

4. No logistics

Say goodbye to monitoring your N2 supply,

and tracking and handling deliveries.

5. Compact setup

All components are designed in the most compact, pre-commissioned layout.

Where is a skid package used?

The PPNG HE skid package is the preferred nitrogen solution for laser cutting. It's also ideal for food and beverage packaging, aircraft tire filling, aerospace manufacturing. In addition, other applications requiring high uptime, purity, flow, and gas quality benefit from a skid.

Our nitrogen generation services – more than just hardware

Ash Air does much more than provide top-quality nitrogen generators:

- As New Zealand's air treatment and gas generation specialist, we can meet all your compressed air quality and industrial gas needs.

- When you provide us with information about your specific nitrogen needs, we can put together the optimal system to meet them.

- We can help with leak detection, flow monitoring and other ways to make nitrogen and compressed air generation more efficient and save you money.

Contact us!

Undecided if a nitrogen skid is right for you? Here at Ash Air we are always ready to put together the nitrogen solution that best meets your needs. Reach out today to get started.