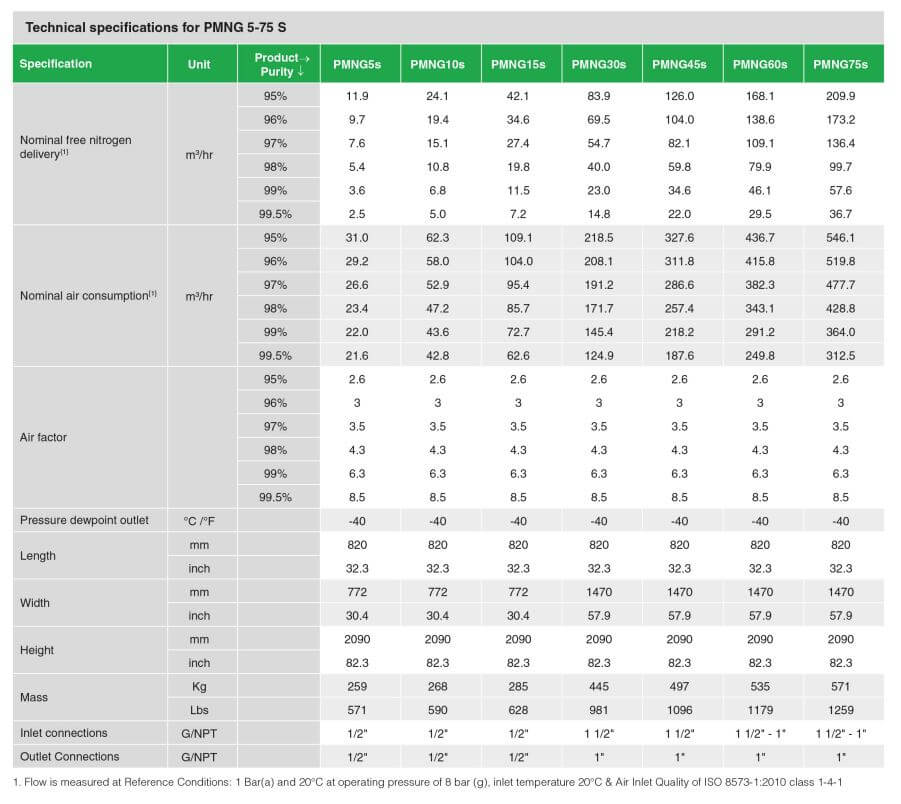

Pneumatech PMNG Series - Membrane Nitrogen Generator

- Overview

Membrane Nitrogen Generators

Pneumatech’s PMNG nitrogen generators utilize proprietary membrane separation technology. Membrane generators are an excellent choice in low (95%) to medium (99,5%) purity applications such as tire inflation, fire prevention, tank blanketing and pipeline drying. Nitrogen pressures can go up to 12 barg without the need for an additional booster. With the PMNG, on-site nitrogen supply becomes exceptionally convenient. All pre-filters and controls are included inside the canopy. Only a supply of dry compressed air and electricity is needed to get nitrogen at the outlet of the generator. An outlet buffer vessel is not required, which results in significant space savings and easy installation. Also the start-up procedure of the PMNG is made so straightforward that it does not require any specialist.

Engineered for simplicity, durability and ease of use make the PMNG what we believe to be the most user friendly unit in the market. All pre-filters and controls are included inside the canopy. Only a supply of dry compressed air is needed to get nitrogen at the outlet of the generator. Also the start-up procedure of the PMNG is made so straightforward that it does not require any specialist.

✓ Proprietary membrane technology ensuring lasting performance

- No aging

- No heater

✓ Guaranteed purity

- Reliable purity measurement

- Easy to set up the device for purity levels between 95% and 99,5%

✓ All-in-one plug & pay solution

- All filters integrated in enclosed canopy design

- No buffer vessels required

- Instant supply of nitrogen

- No specialist installation or commissioning

✓Energy-saving control

✓Optimal control and monitoring thanks to Purelogic controller

Features

Advanced energy saving control

- Reduced air consumption at low nitrogen demand

- Also compensates for altering ambient conditions and purity settings

- No compressed air use when no nitrogen is consumed

Optimal control and monitoring thanks to PurelogicTM Controller

- Self-protective monitoring of the feed air quality

- Feed-air blow-off in case of contamination

- Nitrogen flow, purity and pressure measured and controlled

- Automatic start-up

High-quality, high-efficient Carbon Molecular Sieves selected for the right application

Guaranteed purity

- Automatically regulates to the requested nitrogen pressure andpurity

- Zirconia sensors for reliable purity measurement

Designed & tested for cyclic load

Outstanding air factors thanks to back-flow pressurization

How Can I Increase or Decrease the Purity of my Nitrogen Generator?

Problem: I need different purities of nitrogen for various processes at my facility. How can I change the purity on my nitrogen generator?

Solution: Pneumatech Nitrogen Generators purity levels depend on the control flow through the carbon molecular sieve (CMS) of the unit. Low flow results in higher purity and high flow results in lower purity.

The flow is influenced exclusively by the pressure difference between the air vessel and the nitrogen vessel. The higher the pressure difference, the higher the flow. The generator is sized to deliver 100% nitrogen to the nitrogen vessel during normal operation. When the application consumes less than 100% of the generator's capacity (example: 30%), the generator is able to maintain the pressure in the nitrogen vessel at a constant level. This also means the pressure diffference between the air and nitrogen vessels remains constant. This results in a stable flow through the generator's adsorbant and a stable purity. When the needle valve is opened further, more flow from the nitrogen vessel can be consumed. If this flow consumption is higher than the maximum flow the generator can deliver (example: 150%), the pressure in the nitrogen vessel will decrease. With this, the pressure difference between the air and nitrogen vessel will increase, resulting in a high flow through the adsorbant because the air vessel pushes high pressure air to the nitrogen vessel which is at a low pressure. Due to this high flow through the adsorbant, the purity will decrease.

An illustration of this purity process is included below: