Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

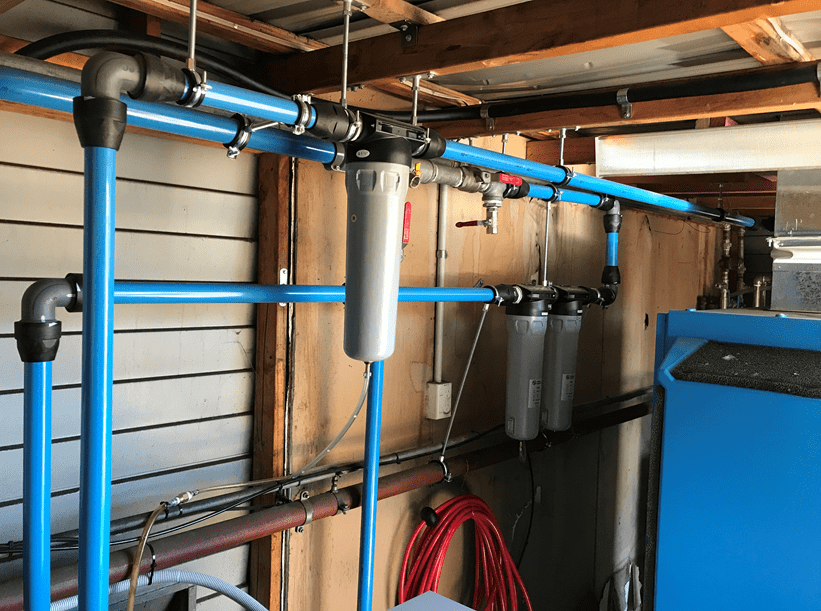

Air compressors create the energy used by pneumatic tools and processes throughout your compressed air system. The component that connects

everything together is the piping. It is very important to choose the right compressed air pipe to avoid pressure

loss, rust and other problems. Below are some of the factors which are important in choosing the right compressed air pipe:

AIRnet

is a piping solution that guarantees operational excellence for compressed air applications.

AIRnet

is a piping solution that guarantees operational excellence for compressed air applications.

Below are the advantages of AIRnet:

1) EASY: With AIRnet there is no need for heavy tools or extra manpower.

TAKE IT EASY • One person can safely handle and install AIRnet. While solid and robust, aluminum AIRnet pipes weigh five times less

than galvanized pipes. • AIRnet is installed with simple tools. No welding, gluing or crimping is required. Welding or lathe machines are a

burden of the past. • AIRnet offers a full scope of materials including pipes, fittings and accessories.

2) FAST: Installing a piping system is no longer time consuming, thanks to AIRnet. READY? SET? DONE! • The

pipes are easy to cut, and the polymer or aluminum fittings ensure a perfect alignment instantly. • AIRnet does not require painting. In

compliance with industrial standards, AIRnet pipes are standard painted for simple network identification. • AIRnet is adaptable to any

existing pipe work. Future extensions can simply be plugged in.

3)

RELIABLE: The

reliability of AIRnet is not a hollow promise; it is a solid 10-year guarantee. THE RIGHT STUFF • AIRnet consists of aluminum

and polymers, highly durable materials suitable for compressed air as well as for vacuum and nitrogen gas. • AIRnet is resistant to

corrosion, mechanical shocks, thermal variations and outdoor weather conditions. • The AIRnet leak-resistant connections offer superior

sealing.

3)

RELIABLE: The

reliability of AIRnet is not a hollow promise; it is a solid 10-year guarantee. THE RIGHT STUFF • AIRnet consists of aluminum

and polymers, highly durable materials suitable for compressed air as well as for vacuum and nitrogen gas. • AIRnet is resistant to

corrosion, mechanical shocks, thermal variations and outdoor weather conditions. • The AIRnet leak-resistant connections offer superior

sealing.

Key Features -

No corrosion, leak resistant - Press fit system ensures fast installation - No welding, no threading: just push & press - It saves you

up to 85% on installation time - High Quality Performance The

piping in your compressed air system can make or break the profitability of your company. Inefficient or faulty piping can wipe out your

profit margin and give your competitors an advantage.

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a reputation for quality and reliability.We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, Alup, Pneumatech, and Quincy compressors are used extensively around the world in industries ranging from oil and gas to food, automotive and farming, and we bring you these world class compressors here in the land of the long white cloud.Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported by a 13 locations nationwide, Ash Air offers one of the widest selections of compressed air equipment and parts available today in New Zealand.

With Ash Air compressors, you can count on reliability and high performance for even the most demanding applications. We focus our efforts on the following:

Talk to the team today:

Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Maintenance budget: 8 factors to consider

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for maintenance can have potentially disastrous consequences. Read More…

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause complete dryer failure. Read More…

Why Replace CO2 with Nitrogen in your Brewery

Using nitrogen is not about fully replacing CO2, but it can reduce their consumption of CO2 by close to 70%. Using nitrogen is about sustainability. Creating your own nitrogen is easy and will reduce the use of a greenhouse gas, which is better for the environment. It will also save you money as early as month one adding that savings to your bottom line. Read More…

What do I need to know about ICONS?

ICONS: Intelligent Connectivity System: The insight into your compressed air system, wherever you are. Learn More about ICONS in this article here! Read More…

A question that is occasionally asked by our customers to Ash Air is 'what is the cost of compressed air?' This article looks at the product costs involved with compressed air, as well as minimising the energy cost of compressors and cost allocation. When looking at these factors, we need to realise what causes dropped efficiency of your compressor, leading to increased costs of compressed air. Read More…