Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

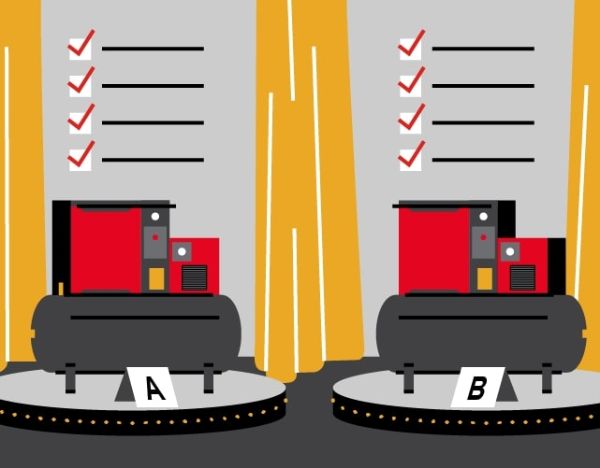

The basic difference between the two technologies can be found right in the name. Fixed speed compressors run at a continuous fixed speed and tend to be very efficient when operating at 100% of its capacity, meaning when the motor is running and compressed air is being manufactured. The inefficiency of a fixed speed compressor is very noticeable and can easily be measured when the unit unloads and stops making air. Before the motor comes to a complete stop, it will continue to run while no air is being produced, consequently wasting energy and money. Inefficiency and waste can especially be visible at facilities that operate multiple shifts and or have great flow demand fluctuation throughout the day.

Variable speed drive (VSD) technology works on a different principle, as it turns the motor at the appropriate speed in relation to the amount of air that is required within a given plant / facility. In simpler terms, as the need / demand for air increases, so does the speed of the motor, therefore supplying more flow / CFM. On the other hand, if the demand decreases, the motor will automatically slow down and only use the required energy to provide appropriate flow. VSD air compressors match the output to the demand that is needed and can sense how much flow is being used, while adjusting its speed accordingly. On slower production days, break throughout the day, or during second and third skeleton shifts, the VSD technology comes especially handy, as it eliminates the waste of electricity, therefore saving money.

Considering that compressed air usage is costly, as it accounts for over 70% of Total Cost of Ownership in electricity costs, utilizing VSD technology can help you achieve savings of 35-50%. Depending on size of the compressor, the savings can range from $100s to $10,000s annually or more, making it an ideal investment for any facility. VSD air compressors are becoming the norm rather than an exception, with many customer enjoying the annual energy savings and having the ability to reinvest the money into other assets.

For any questions in regards to compressors and which one would work best for your industry, please contact is on 0800 274 247 or help@ashair.co.nz

.png)

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a reputation for quality and reliability.We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, Alup, Pneumatech, and Quincy compressors are used extensively around the world in industries ranging from oil and gas to food, automotive and farming, and we bring you these world class compressors here in the land of the long white cloud.Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported by a 13 locations nationwide, Ash Air offers one of the widest selections of compressed air equipment and parts available today in New Zealand.

With Ash Air compressors, you can count on reliability and high performance for even the most demanding applications. We focus our efforts on the following:

Talk to the team today:

Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Maintenance budget: 8 factors to consider

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for maintenance can have potentially disastrous consequences. Read More…

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause complete dryer failure. Read More…