Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

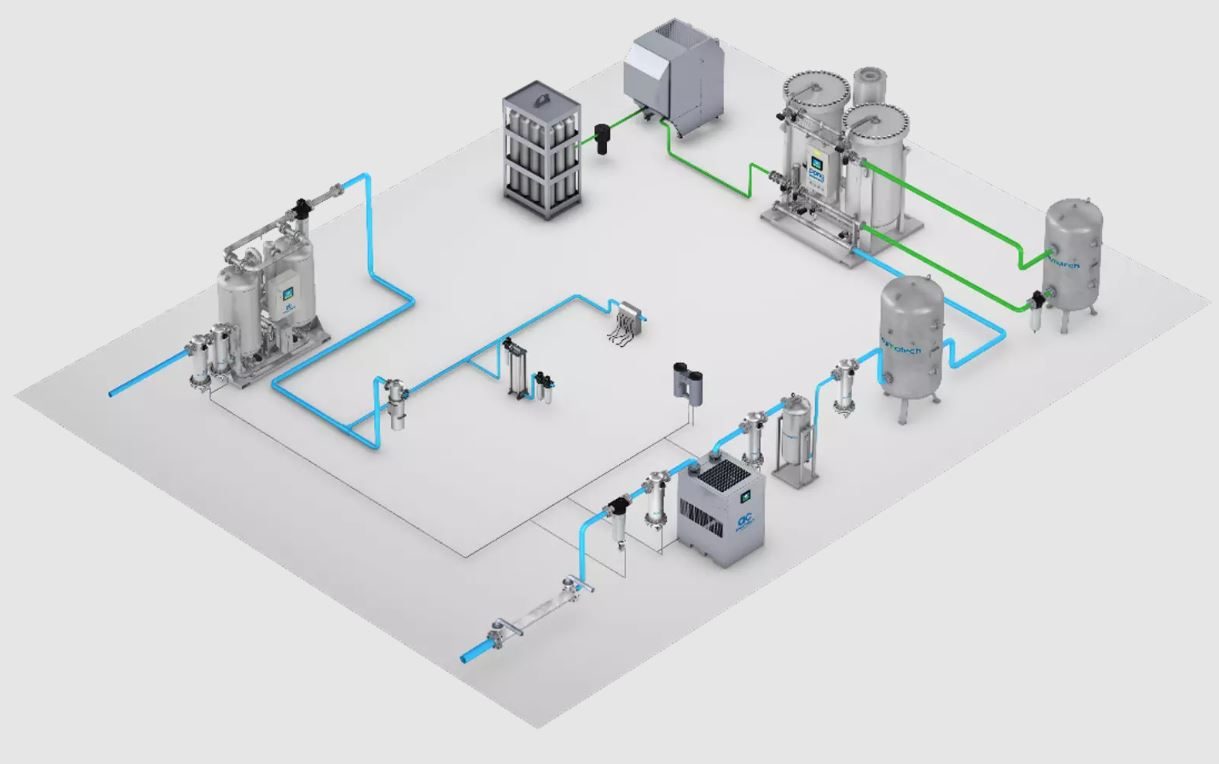

Compressed

air treatment is a method that dehumidifies and cleans after it leaves the air compressor. This is done using an air dryer and an additional

filter beyond the air filter found in a compressor. Air is always contaminated with solid particles such as dust, sand, soot, salt crystals

and water as it leaves the compressor. An effective compressed air treatment system lowers the dew point of the air and takes out the

elements that may harm equipment downstream of the compressor and dryer. Remember the higher the ambient temperature is, the higher the

ability to hold moisture. Water contamination can also lead to microbial contamination, corrosion, blocked or frozen valves, cylinders, air

motors and tools and premature wear/failure of equipment. Water contamination of compressed air systems can reduce production efficiency and

increase manufacturing costs.

Compressed

air treatment is a method that dehumidifies and cleans after it leaves the air compressor. This is done using an air dryer and an additional

filter beyond the air filter found in a compressor. Air is always contaminated with solid particles such as dust, sand, soot, salt crystals

and water as it leaves the compressor. An effective compressed air treatment system lowers the dew point of the air and takes out the

elements that may harm equipment downstream of the compressor and dryer. Remember the higher the ambient temperature is, the higher the

ability to hold moisture. Water contamination can also lead to microbial contamination, corrosion, blocked or frozen valves, cylinders, air

motors and tools and premature wear/failure of equipment. Water contamination of compressed air systems can reduce production efficiency and

increase manufacturing costs.

Both

refrigerated and desiccant dryers are needed in many industrial applications to produce/protect final products, as well as to protect much

of the pneumatic equipment that is used in many industrial facilities. Food/beverage packaging and manufacturing companies use dryers to

prevent their actuators and assembly machinery from rusting or collecting moisture in the lines that prevents clean compressed air from

flowing. Dryers are also used in textiles to keep fabrics free of moisture and to aid in the texture of produced products. Many electronics

manufacturers need high levels of dry air so that humidity will not transfer over to the production of computers, cell phones, televisions,

etc. These same industries often use moisture separators, oil-water separators and aftercoolers to further aid in the drying process, as

well as removal of contaminants from any compressed air flow. Dust, dirt or other small particles are present in compressed air until they

are removed by using filters, separators and mist eliminators. Air treatment is necessary in almost all compressed air applications. From

food manufacturing, to brewing beer, to building electronics, having dry compressed air is a must to prevent product and equipment damage.

Both

refrigerated and desiccant dryers are needed in many industrial applications to produce/protect final products, as well as to protect much

of the pneumatic equipment that is used in many industrial facilities. Food/beverage packaging and manufacturing companies use dryers to

prevent their actuators and assembly machinery from rusting or collecting moisture in the lines that prevents clean compressed air from

flowing. Dryers are also used in textiles to keep fabrics free of moisture and to aid in the texture of produced products. Many electronics

manufacturers need high levels of dry air so that humidity will not transfer over to the production of computers, cell phones, televisions,

etc. These same industries often use moisture separators, oil-water separators and aftercoolers to further aid in the drying process, as

well as removal of contaminants from any compressed air flow. Dust, dirt or other small particles are present in compressed air until they

are removed by using filters, separators and mist eliminators. Air treatment is necessary in almost all compressed air applications. From

food manufacturing, to brewing beer, to building electronics, having dry compressed air is a must to prevent product and equipment damage.

If you have any questions on setting up air treatment or sizing your next dryer, please contact us.

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a

reputation for quality and reliability.We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, Alup, Pneumatech, and Quincy compressors are used extensively around the world in industries

ranging from oil and gas to food, automotive and farming, and we bring you these world class compressors here in the land of the long white

cloud.Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported by a 13 locations

nationwide, Ash Air offers one of the widest selections of compressed air equipment and parts available today in New Zealand.

With Ash Air compressors, you can count on reliability and high performance for even the most demanding applications. We focus our

efforts on the following:

Talk to the team today:

Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider.

Read More…

Maintenance budget: 8 factors to consider

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire

lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for

maintenance can have potentially disastrous consequences.

Read More…

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause

complete dryer failure.

Read More…

Why Replace CO2 with Nitrogen in your Brewery

Using nitrogen is not about fully replacing CO2, but it can reduce their consumption of CO2 by close to 70%. Using nitrogen is about

sustainability. Creating your own nitrogen is easy and will reduce the use of a greenhouse gas, which is better for the environment. It will

also save you money as early as month one adding that savings to your bottom line.

Read More…

What do I need to know about ICONS?

ICONS: Intelligent Connectivity System: The insight into your compressed air system, wherever you are. Learn More about ICONS in this article here!

Read More…

A question that is occasionally asked by our customers to Ash Air is 'what is the cost of compressed air?' This article looks at the

product costs involved with compressed air, as well as minimising the energy cost of compressors and cost allocation. When looking at these

factors, we need to realise what causes dropped efficiency of your compressor, leading to increased costs of compressed air.

Read More…

Do you have an idea for our #expertcorner? Let

us know!

Who we are and how Ash Air can help your business!

Reliability and Efficiency

Read more from our #expertcorner