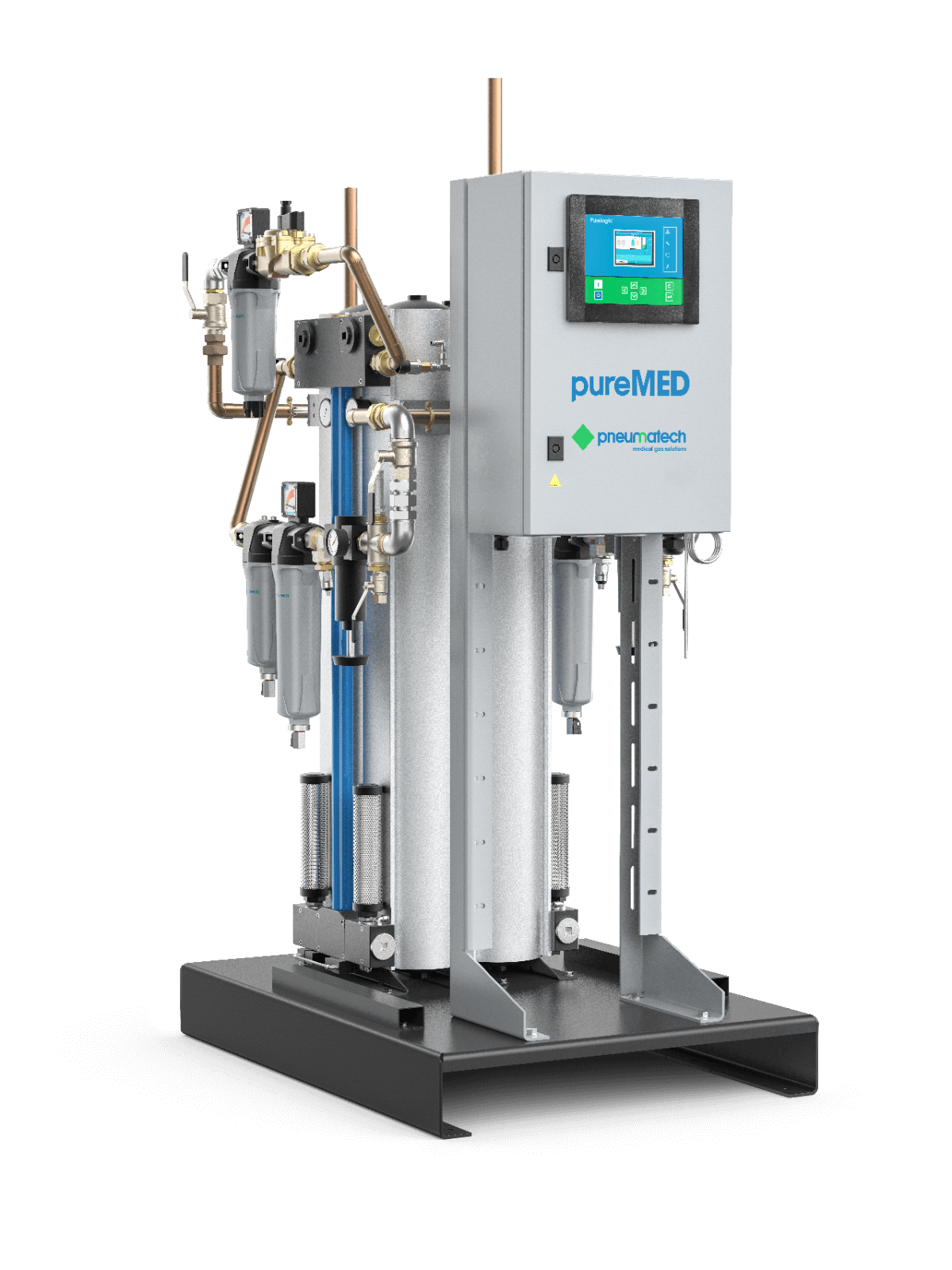

Medical Air Plant

Our medical air plant provides you ultra-clean medical air, that is required for medical and surgical

applications

Medical air solutions fully adaptable to your needs

Our Medical Air Plant provides a reliable, centralised medical air supply. Systems are available from simplex up to hexaplex configurations. They are supplied as a fully modular assembly ensuring ease of on-site installation.

The systems consist of carefully designed medical compressors with after coolers, air receiver(s), duplex filtration dryer and pressure regulation assembly, all necessary control cabinets, circuitry and interconnecting cabling.

State-of-the-art control

Our Purelogic™ Central Controller provides optimal control and monitoring of your machines, increased reliability and reduced energy consumption.

Flexible system layout

We offer our Medical Air System as a modular configuration for easy on-site installation and maintenance.

Easy to install

Interconnecting pipework between components are made on-site and provided by the installer. Controller CAN cables are provided as a 10m assembly with each compressor that can be shortened if required.