Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

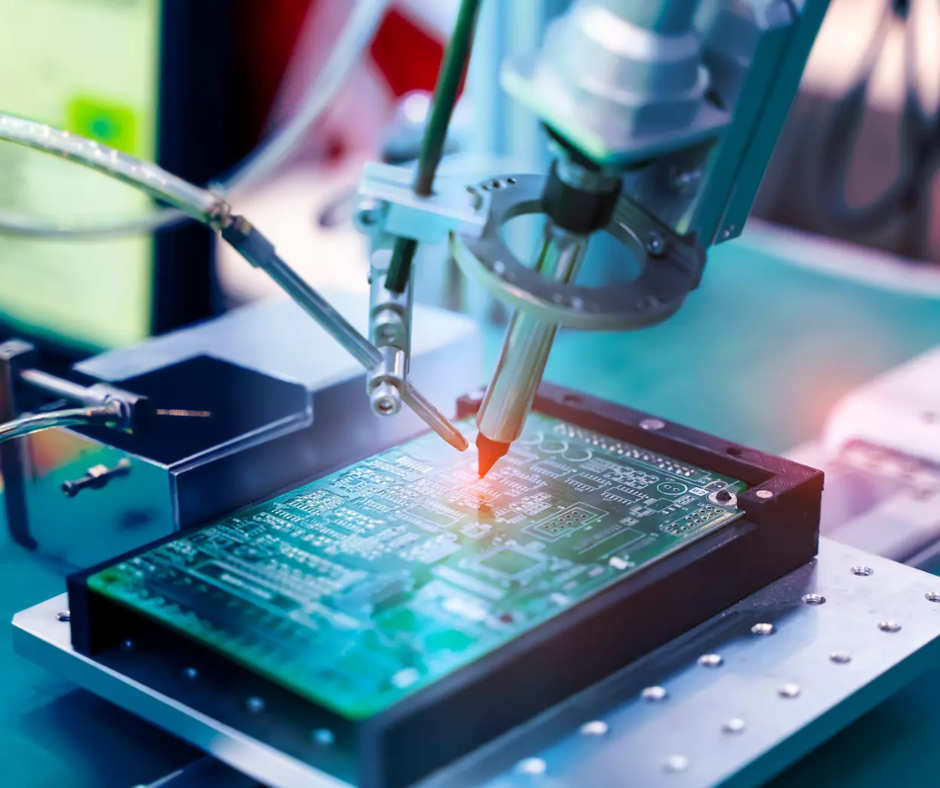

Selective

soldering with nitrogen is an essential process in the production of printed circuit boards (PCBs). It is used for bonding components to

PCBs that could otherwise be damaged if exposed to a lot of heat. Another area of application are mixed-technology circuit boards with

layout constraints.

Selective

soldering with nitrogen is an essential process in the production of printed circuit boards (PCBs). It is used for bonding components to

PCBs that could otherwise be damaged if exposed to a lot of heat. Another area of application are mixed-technology circuit boards with

layout constraints.

Selective soldering is an automated process. It gives you the precision of hand soldering with none of its delays and inconsistencies.

Different soldering methods are available for PCB production. The most common are wave, selective soldering and reflow soldering. In the choice between these options, selective soldering offers distinct benefits:

Because of its inert properties, nitrogen is applied in soldering to ensure the process is free from oxygen. That is because oxygen would react with the solder. This would create an oxide layer that can lead to quality problems or short circuits in the selective soldering units.

Many companies rely on nitrogen deliveries. However, this option comes with a high cost of gas. You not only have to pay a lot for the nitrogen itself but also for rental fees for the nitrogen cylinders. In addition, purchasing nitrogen from a vendor requires you to free storage space, which can lead to supply bottlenecks and logistics headaches.

A much better alternative is on-site nitrogen generation with a compressor and a nitrogen generator.

This eliminates these challenges while also offering a series of additional benefits. First and foremost is the reduction in costs. A cubic meter of nitrogen generated on-site is significantly cheaper than a cubic meter of purchased nitrogen.

Equally important is supply control. Nitrogen is critical to your soldering activities. Can you really afford to be dependent on third party suppliers?

In addition, a nitrogen generator allows you to select the required gas purity. This is critical in ensuring appropriate solder spreading behavior at low temperatures. Setting the right purity also allows you to reduce your energy and thus operating costs.

Finally, you can eliminate the transport emissions associated with gas deliveries and lower your carbon footprint.

Different factors determine the effectiveness of the selective soldering process. These include the configuration of the machine, the attributes of the flux, and the nozzle choice. And, of course, the nitrogen you use is important. You have to make sure it is of the right purity to prevent dross formation. High-purity nitrogen can also extend the lifetime of the nozzles, which saves costs.

A nitrogen generator from Pneumatech is the optimal solution for providing you with a steady supply of high-quality nitrogen. This not only lowers your operating costs but also can help you to take your selective soldering operation to the next level. To learn more, contact one of our experts now.

Sourced from: https://www.pneumatech.com/en-international/blog/

Do you have an idea for our #expertcorner? Let

us know!

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a reputation for quality and reliability.We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, ALUP, Pneumatech, and Atlas Copco products are used extensively around the world in industries ranging from oil and gas to food, automotive and farming, and we bring you these world-class compressors here in the land of the long white cloud.Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported with nationwide coverage, Ash Air offers one of the widest selections of compressed air, vacuum pump, and industrial gas equipment and parts available today in New Zealand.

With Ash Air, you can count on reliability and high performance for even the most demanding applications. We focus our efforts on the following:

Talk to the team today:

Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Maintenance budget: 8 factors to consider

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for maintenance can have potentially disastrous consequences. Read More…

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause complete dryer failure. Read More…