Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

If you're reading this, you probably know the usefulness of air compressors. Air compressors are used worldwide to efficiently operate various tools and machinery. Whether gas or electric, air compressors are an essential piece of operation for many industries. One of the only real drawbacks of many air compressor is the noise.

There are a few factors that make air compressors so loud, but most of the noise can be attributed to friction. Metal hitting or sliding against metal can be loud! Typically, the more moving parts the air compressor has, the louder it may be. This is true in the motor as well, Gaspowered compressors create combustion and have many moving metal parts, therefore they are bound to be louder than electric compressors.

The environment around your compressor can also contribute to the noise. The noises made by your compressor can be amplified by smooth concrete floors and open areas.

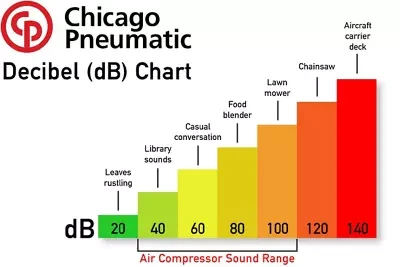

The decibel (dB) is a measurement unit that is frequently used to measure the intensity of sound. The higher the decibel measurement, the louder the noise; but it's not a straightforward scale. A sound of 50dB is going to be more than twice as loud as 25dB noise. This increase continues along the scale. The below image provides some example of this.

It is fairly common for a medium-to-large business to use a compressor room. It is a way to streamline installation, connectivity and future expansion. While it will keep the noise in one spot, it will not eliminate the noise. When it comes to the maintenance on one of the compressors, the noise of the others will be deafening unless you shut them all down.

Most air compressors operate from 40dB to 100dB, this is a large range (roughly a quiet office to a lawnmower). The possible effects of loud compressors include:

While all these problems are significant, the most dangerous problems are the potential health issues that can be caused by prolonged exposure to loud noises. It is recommended for people around noises above 85dB to wear hearing protection. As we have already established, many air compressors are in that range and even higher.

If company noise safety policies are loose or not enforced, employees who are around loud compressors for a lengthy amount of time could develop noise induced hearing loss (NIHL). NIHL can be caused by prolonged exposure to regular loud noises or singular exposures to extremely loud noises. Another hearing issue is tinnitus. Tinnitus is also caused by loud noises and causes a persistent ringing in your ears. It has the potential to get nad enough that you cannot hear past the ringing.

Even if your business is not loud enough to cause hearing damage, it could negatively affect your business. Many small businesses operate with limited space due to cost restictions, which means face to face customer interactions or phone calls may take place near a compressor. Conversations could be interrupted by compressors switching on and could potentially make your business seem less professional.

Luckily, covering your ears is not the only solution to the noise problem. Air Compressors have evolved since they were first introduced and not all of them are the noise machines that we are used to. As mentioned earlier, some air compressors have the capability to run as quietly as 40dB, which is like the ambient noise of a library. This volume won't hurt your ears or distract you from work.

Low volume air compression is possible with our range of compressors. Our screw compressors have been designed to provide constant

airflow while also running at a much lower volume than traditional piston compressors. The

rotary screw element eliminates a multitude of moving parts, making these models quiet and efficient. They also feature castings that cover

all of the workings, which dampens the sound significantly.

Contact us today learn more about how to quiet your environment by switching to an Ash Air recommended compressor. We're here to answer your questions and connect you to an expert in your area who can come to your facility and assess your specific needs.

Do you have an idea for our #expertcorner? Let

us know!

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a reputation for quality and reliability.We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, ALUP, Pneumatech, and Atlas Copco products are used extensively around the world in industries ranging from oil and gas to food, automotive and farming, and we bring you these world-class compressors here in the land of the long white cloud.Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported with nationwide coverage, Ash Air offers one of the widest selections of compressed air, vacuum pump, and industrial gas equipment and parts available today in New Zealand.

With Ash Air, you can count on reliability and high performance for even the most demanding applications. We focus our efforts on the following:

Talk to the team today:

Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Maintenance budget: 8 factors to consider

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for maintenance can have potentially disastrous consequences. Read More…

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause complete dryer failure. Read More…