Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Our passion for energy efficiency and cost saving derives from the concern for our children’s future. Analysing the efficiency of your system is a brilliant way to start saving.

Compressed air leaks can commonly account for 20-50% of a plant’s total compressed air consumption. Frequently, fixing leaks is as simple as tightening a loose connector and as such can provide an extremely attractive payback period. Ash Air have qualified technicians for ultrasonic air leak detection, who can not only detect the leaks but can provide on the spot repairs. Most leak detetion programs that are carried out do not offer this service as standard but at Ash Air we can save you money from the minute we start on your site.

Compressed air leaks can commonly account for 20-50% of a plant’s total compressed air consumption. Frequently, fixing leaks is as simple as tightening a loose connector and as such can provide an extremely attractive payback period. Ash Air have qualified technicians for ultrasonic air leak detection, who can not only detect the leaks but can provide on the spot repairs. Most leak detetion programs that are carried out do not offer this service as standard but at Ash Air we can save you money from the minute we start on your site. Our certified engineers can analyse your system with leak detection equipment and data loggers and suggest the best solution for you.

The benefits of a Compressed Air Audit, are the potential reductions in the operating costs for the end user; this in turn will improve the productivity of the manufacturing process. Ash Air can tailor a compressed air audit to suit your needs. If a walk through audit is sufficient one of our team of trained staff can carry this out, and feed this information back to you in a professional report with actions and recommendations.

We can also offer full in depth audits; with a comprehensive data logging of your compressed air equipment on site. As a result of this, we can propose recommendations to enhance the operation of your equipment on site. Energy represents the largest cost associated with operating an industrial compressor and therefore represents the largest opportunity for savings. One way Ash Air can help to calculate your energy consumption is through the use of a data loggers. During off load running, fixed speed compressors deliver no air but can still consume between 20-40% of full load power.

At Ash Air we know it's important to understand a users air demand so that the best solution can be identified in order to save energy losses. Data Loggers can be connected to the incoming electricity supply which records a reading of the incoming Amps every 90 seconds over a seven day period. This data is then downloaded from the data logger into a software package. Graphs and reports can be produced to simulate and calculate energy consumption. This data can then be analysed to produce a demand profile for the compressor system and subsequently an accurate compressor profile can be recommended. Installing the correct compressor for your system requirements is the first step in saving energy and reducing your energy costs.

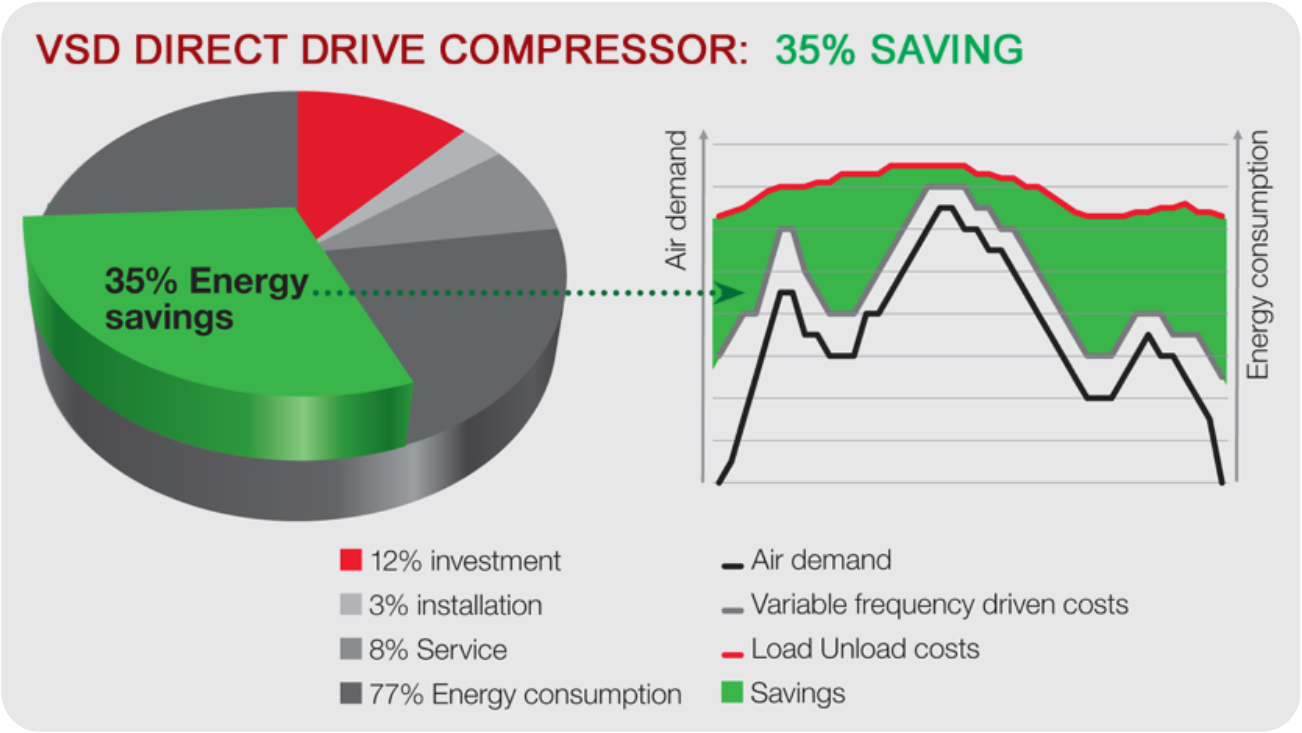

Variable Speed Drive (VSD) compressors can save up to 30% of system energy costs. We have various VSD models to suit your air requirements and working conditions

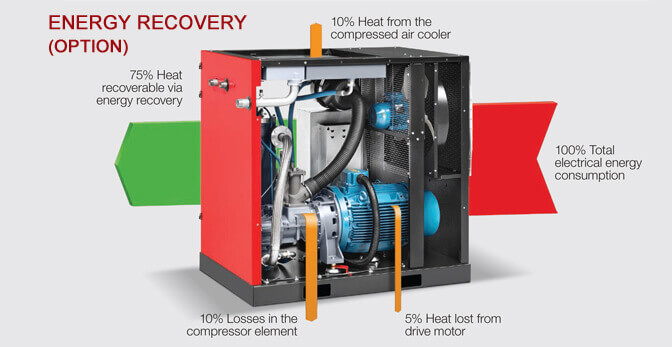

The energy recovery option can capture heat and recover up to 75% of energy loss.

Get in touch and see how we can help you today!

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a

reputation for quality and reliability.We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, Alup, Pneumatech, and Quincy compressors are used extensively around the world in industries

ranging from oil and gas to food, automotive and farming, and we bring you these world class compressors here in the land of the long white

cloud.Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported by a 13 locations

nationwide, Ash Air offers one of the widest selections of compressed air equipment and parts available today in New Zealand.

With Ash Air compressors, you can count on reliability and high performance for even the most demanding applications. We focus our

efforts on the following:

Talk to the team today:

Do you have an idea for our #expertcorner? Let

us know!

Who we are and how Ash Air can help your business!

Reliability and Efficiency

Read more from our #expertcorner

Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Maintenance budget: 8 factors to consider

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for maintenance can have potentially disastrous consequences. Read More…

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause complete dryer failure. Read More…