Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Once you have the size and type of

compressor figured out, one last question remains, should I go with an oil lubricated or oil-free air compressor. To not overcomplicate the

answer, your choice should be based on the application and process that the compressed air will be utilized in.

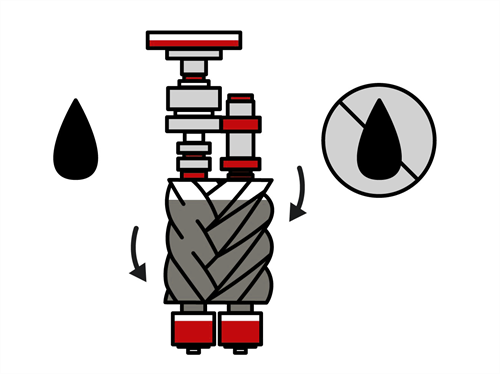

The first step in selecting any compressor is assessing your facility’s needs. There are instances where the consequences of oil contamination are too high, therefore having an oil-free air compressor is a must. However, the majority of manufacturing, industrial and small workshops utilize oil injected compressors, since the consequences of oil contamination are not as great as they would be in a food production facility for example. Oil in air compressors is utilized to lubricate, seal and also cool the compressed air.

If there is no immediate need for oil-free compressed air, the more economic way is to go with an oil lubricated unit like an oil-injected screw compressor. Oil-free compressors carry a much greater cost. Although, there are traces of oil in compressed air, those can be cleaned up further by utilizing proper quality air products. The use of coalescing filters can clean the compressed air down to 0.01 micron, which can further be cleaned by adding a carbon activated filter to get close to Class 1 air purity.

Oil-free air compressors are used to produce a wide range of sensitive products, from semiconductors, medication and paper. Even the smallest trace of oil in such applications could have adverse effects on products and even people. Class 0 and “technically oil-free” are often used to imply that a compressor meets certain standards. Although, these terms are similar they have key differences that if not taken under consideration can lead to unintended consequences.

To better understand it all, let’s take a deeper look at the meaning of 'Oil-fee'. Oil-free and oil-less are both used to describe compressors that do not use any lubrication in the compression chamber. While the first two terms describe a type of compressor, Class 0 and “technically oil-free” express how clean the air is after compression. There are important differences between the two, which we will explain later on in this article.

The International Organization for Standardization (ISO) sets forth worldwide standards for proprietary, industrial and commercial purposes. Compressed air has its own set of ISO standards. Depending on the ultimate air purity (determined by number of particles per cubic meter as a function of particle size), compressors can be ranked from ISO Class 0-5. The original version of ISO compressed air purity standards (1991) was ‘made by and made for’ the filter manufacturers. The standard defined five classes of oil concentration, the best of which was Class 1.

ISO Class 1 - Technically Oil-Free Air

Class 1 specifies an oil concentration of 0.01 mg/m3 at 1 bar(a) 14.5psia and 20oC (68F), and conformance to these criteria is sometimes called “a technically oil-free solution.” However, these standards were edited in 2001 and were further updated in 2010. The current standard sets limits on total oil content (aerosol, liquid and vapor), and a specific standard was introduced on measurement of oil vapor.

ISO Class 0 - Oil-Free Air

A new class (Class 0) was added to cover more stringent quality requirements. ISO Class 0 is the cleanest choice. They can guarantee 100 percent oil-free air. There are some faulty claims going around the industry that promote oil lubricated compressors with filters and calling them “technically oil-free” as well as stating that the air quality is often better than that from an oil-free compressor. These claims are untrue and their use when Class 0 is needed can lead to inadvertent damage to sensitive products and or equipment.

When choosing an oil-free compressor, make sure to pick a Class 0 oil-free compressor and not a “technically oil-free” option. They generally have a higher initial price point, but they are much safer to use in sensitive applications. With Class 0, you can be sure that absolutely no contamination will reach your end user equipment and rest assured that your assets are protected. It is always best practice to seek advice from a compressed air professional when picking out an oil-free or oil lubricated air compressor.

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a reputation for quality and reliability.

We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, Alup, Pneumatech, and Quincy compressors are used around the world in industries ranging from oil and gas to food, automotive and farming, and we bring you these world class compressors here in the land of the long white cloud.

Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported by a 13 locations nationwide, Ash Air offers one of the widest selections of compressed air equipment and parts available today in New Zealand.

With Ash Air compressors, you can count on reliability and high performance for even the most demanding applications. We focus our efforts on the following:

We offer a broad array of products, from world class compressor brands, including a full range of rotary and reciprocating air compressors from ½ to 200 horsepower. We serve the compressed air needs of many industries such as the following:

In our effort to prioritise the needs of our customers, we work hard to provide solutions. We continually introduce innovative products here at Ash Air to our Kiwi customers, so our end users can rely on us to meet evolving compressed air needs.

We offer an extensive array of air compressor parts and services through our direct locations throughout New Zealand. Continued growth means our operations continue to operate on a national level.

In our effort to provide the best possible support, we offer the following remote monitoring, preventative maintenance, vacuum pump services and overhaul, compressor and pipework installations, hire fleet and leasing solutions, leak detection's and energy audits, and breakdown recovery and emergency air.

When considering new energy-efficient air compressors or an upgrade to more energy-efficient machinery, Ash Air can help you make the right choices for your business.

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a

reputation for quality and reliability.We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, Alup, Pneumatech, and Quincy compressors are used extensively around the world in industries

ranging from oil and gas to food, automotive and farming, and we bring you these world class compressors here in the land of the long white

cloud.Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported by a 13 locations

nationwide, Ash Air offers one of the widest selections of compressed air equipment and parts available today in New Zealand.

With Ash Air compressors, you can count on reliability and high performance for even the most demanding applications. We focus our

efforts on the following:

Talk to the team today:

Do you have an idea for our #expertcorner? Let

us know!

Useful links:

Book Your Compressor Service

Who we are and how Ash Air can help your business!

Reliability and Efficiency

Read more from our #expertcorner

Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Maintenance budget: 8 factors to consider

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for maintenance can have potentially disastrous consequences. Read More…

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause complete dryer failure. Read More…