Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

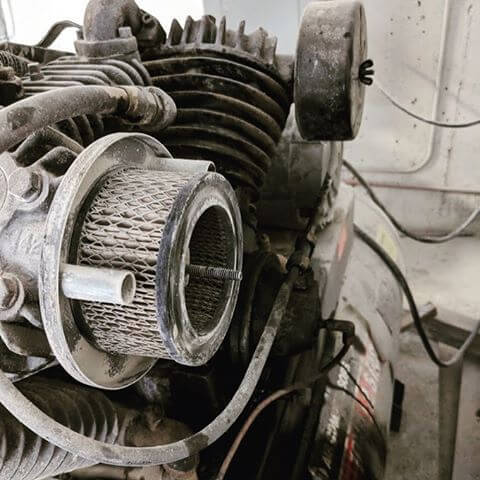

An air compressor is a big purchase for any business. It is visibly important to properly maintain the air compressor and filter elements to protect that investment. Air intake filters are installed in an air compressor to remove any dust or debris the compress may suck in. Dust will cause wear to the compressor element, valves, filters, compressor oil and any moving parts.

An unclean air or oil filter causes the compressor to run less efficiently. That costs more money to run and the compressor will need to be replaced sooner.

All Rotary Screw air compressor have three filters; an oil filter, an air inlet filter, and an air/oil separator. Like changing the oil in your machine, replacing the filters will prevent your compressor’s parts from failing prematurely and avoid the oil from becoming contaminated.

Replacing both the air filters and oil filters every 2000 hours of use, at a minimum, is typical. In dirtier environments, the filters may need to be changed more frequently. Separators are typically manufactured to be used for 8000 hours. But there are some machines that require the separator to be changed more frequently. This is outlined in your service manual.

Change your air compressor filters twice a year. Who's heard that? Don't just take that advice, but actually look for yourself. How's your filter looking?

A filthy air filter is only hurting your air compressor by allowing dirty air from the outside in, plus forcing it to work harder to intake air. If the oil filter gets heavily covered in oily residue before that time, replace it sooner.

As dirt and dust collect on the air filters, impurities move through the system and degrade the quality of compressed air. Moreover, dirty air filters obstruct the systems performance and force the system to exert more energy just to perform basic functions. If the problem persists, dirty air filters can lead to excess energy consumption, costly maintenance and downtime. Rotary screw air compressor overheating is also sometimes the result of clogged air filters.

Oil can damage the quality of the air if it passes through the machine. That oil can get carried to the end of an application. Some of the most affected processes would include pneumatic spray painters, air cleaners and anything else where oil could corrupt the surface. It’s vital to ensure that if oil is present in the system, it is removed from the compressed air before the air leaves the machine.

Your business performance is what we strive for. Ash Air offers a full range of Chicago Pneumatic and Alup air compressors, tools and on-site solutions. We also provide oil-free compressors and food-grade oil to suit your needs. Ash Air are specialists in vacuum pumps, blowers, and medical gas solutions. Ash Air offers complete quality air solutions as well as advanced piping systems for the performance and efficiency of your compressed air system.

Ash Air has been around in New Zealand since 1979, and we’ve grown into a nationwide company with international support and a

reputation for quality and reliability.We look after all things compressed air for your business!

Ash Air's range of Chicago Pneumatic, Alup, Pneumatech, and Quincy compressors are used extensively around the world in industries

ranging from oil and gas to food, automotive and farming, and we bring you these world class compressors here in the land of the long white

cloud.Our technicians are compressed air equipment experts and are dedicated to addressing customer needs. Supported by a 13 locations

nationwide, Ash Air offers one of the widest selections of compressed air equipment and parts available today in New Zealand.

With Ash Air compressors, you can count on reliability and high performance for even the most demanding applications. We focus our

efforts on the following:

Talk to the team today:

Do you have an idea for our #expertcorner? Let

us know!

Useful links

Book Your Compressor Service

Who we are and how Ash Air can help your business!

Reliability and Efficiency

Read more from our #expertcorner

Proportioning the Compressed Air Dryer

Trying to figure out which air dryer capacity is best for you? Here are some factors to consider. Read More…

Maintenance budget: 8 factors to consider

Just like any other equipment, a compressed air installation also requires the necessary maintenance work during its entire lifespan. Even though maintenance costs are only about 5 to 10% of a machine's annual operating costs, failure to budget for maintenance can have potentially disastrous consequences. Read More…

The air dyer is one of the most ignored cooler in the system. A dirty condenser will cause water in the lines, or worse it will cause complete dryer failure. Read More…