About us

.png)

.png)

.jpeg)

Ash Air’s range of Chicago Pneumatic, ALUP, Pneumatech brands are used extensively around the world in industries ranging from oil and gas to food, automotive and farming, and we bring you these world class compressors right here in New Zealand.

We offer a broad array of the highest quality products including a full range of rotary and reciprocating air compressors from 1.5 to over 300 horsepower, nitrogen, vacuum pumps, as well as an extensive line of air treatment components.

We provide market-leading, highly energy efficient industrial compressors; screw, oil-free reciprocating compressors, air and gas treatment equipment, and vacuum systems. Ash Air offers a full range of world class air compressors, tools and on-site solutions.

We provide oil-free compressors and food-grade oil to suit your needs. Ash Air are specialists in vacuum pumps, blowers, and medical gas solutions. We offer complete quality air solutions as well as advanced piping systems for the performance and efficiency of your compressed air system.

Your business performance is what we strive for. Ash Air offers a full range of Chicago Pneumatic and Alup air compressors, tools and

on-site solutions. We also provide oil-free compressors and food-grade oil to suit your needs. We are specialists in vacuum pumps,

blowers, and medical gas solutions. Ash Air offers complete quality air solutions as well as advanced piping systems for the performance

and efficiency of your compressed air system.

With nationwide coverage, you can count on us as your compressed air specialists.

We are passionate about understanding our customers and we have helped them save costs on their compressed air and vacuum systems.

Today Ash Air is trusted by more than 5,500 businesses, large and small, all over New Zealand.

"Ash Air has been pivotal in assisting Air New Zealand Engineering in our energy saving efforts. They provide us with constant improvement programs that include high quality equipment & service, Air Quality Testing, Leak Detection & Repairs and point of use improvements. Air New Zealand Engineering do our best in servicing large jet airframes and Ash Air has always been there to support our compressed air efficiency requirements."

"At Fisher & Paykel Appliances, compressed air and vacuum systems are an important part of our operations. Ash Air understands our needs and can solve our problems very swiftly. They have maintained our systems to a high standard. The service and support from Ash Air over the years has proven to be reliable, professional and genuine. They are highly skilled real people and we are happy to be working with them."

Our passion for energy efficiency and cost saving derives from the concern for our children’s future. Our products and services are both friendly to the earth as well as your business well-being.

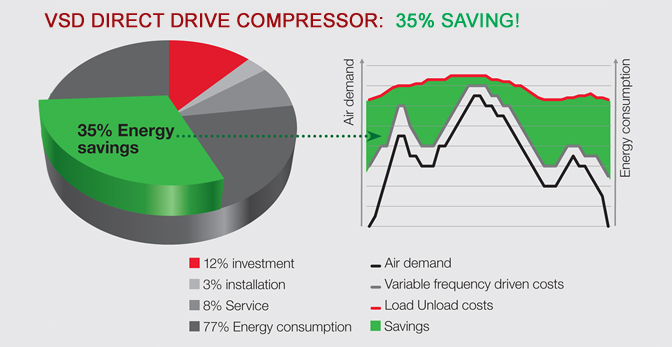

Variable Speed Drive (VSD) compressors can save up to 35% of system energy costs. More than 80% of a compressor’s lifecycle cost comes from the consumption of energy. Therefore we focus on reducing your energy bill by adapting your compressors’ output with the demanded air input.

How it works

Operations have a fluctuating demand for air, so our VSD technology for compressors makes sure that you and your business get the required air at the required time. This makes sure that your compressor is not using more energy than needed , effectively decreasing your energy consumption, and increasing your energy efficiency.

More than 80% of a compressor’s lifecycle cost comes from the consumption of energy. Therefore we focus on reducing your energy bill by adapting your compressors’ output with the demanded air input. On average we save your company 35% of the energy cost usually related to compressor costs. This gives you a competitive advantage.

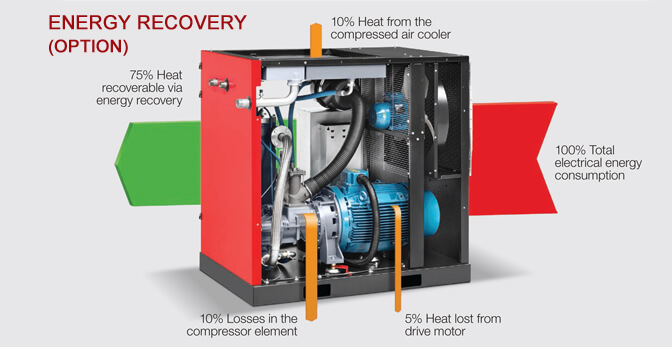

The energy recovery option can capture heat and recover up to 75% of energy loss.

When looking at the typical carbon footprint of an air compressor - from the design phase right through to the equipment’s recycling - the energy consumed in its use accounts for 99% of CO2 emissions. As energy consumption also typically represents over 80% of a compressor’s lifecycle cost, energy savings in compressed air systems will have a significant impact towards preserving not only the environment but also your bottom line. While compressed air systems in general account for about 10% of total industrial electricity consumption, this can amount to as much as 40% of the electricity bill for certain plants.

How does compressor heat recovery work?

Up to 94% of the electrical energy is converted into compression heat. Without energy recovery, this heat is lost into the atmosphere via the cooling system and radiation.

You can use hot water recovered from the compressed air system for sanitary purposes and space heating. But it is particularly suitable for process applications. Using the hot water as boiler pre-feed or directly in processes requiring 70 to 90°C can save you costly energy sources such as natural gas and heating oil.

Compressed air leaks can commonly account for 20-50% of a plant’s total compressed air consumption.

Frequently, fixing leaks is as simple as tightening a loose connector and as such can provide an extremely attractive payback period.

Ash Air have qualified technicians for ultrasonic air leak detection, who can not only detect the leaks but can provide on the spot

repairs. Most leak detetion programs that are carried out do not offer this service as standard but at Ash Air we can save you money

from the minute we start on your site.

ICONS stands for Intelligent Connectivity System which will give you the performance data of your machine.

You will be able to optimise the efficiency and monitor your compressor from

your desk.

The benefits of a Compressed Air Audit, are the potential reductions in the operating costs for the end user; this in turn will improve the productivity of the manufacturing process. Ash Air can tailor a compressed air audit to suit your needs. If a walk through audit is sufficient one of our team of trained staff can carry this out, and feed this information back to you in a professional report with actions and recommendations.

We can also offer full in depth audits; with a comprehensive data logging of your compressed air equipment on site. As a result of this, we can propose recommendations to enhance the operation of your equipment on site. Energy represents the largest cost associated with operating an industrial compressor and therefore represents the largest opportunity for savings.

One way Ash Air can help to calculate your energy consumption is through the use of a data loggers. During off load running, fixed speed compressors deliver no air but can still consume between 20-40% of full load power.

At Ash Air we know it's important to understand a users air demand so that the best solution can be identified in order to save energy losses. Data Loggers can be connected to the incoming electricity supply which records a reading of the incoming Amps every 90 seconds over a seven day period. This data is then downloaded from the data logger into a software package.

Graphs and reports can be produced to simulate and calculate energy consumption. This data can then be analysed to produce a demand profile for the compressor system and subsequently an accurate compressor profile can be recommended. Installing the correct compressor for your system requirements is the first step in saving energy and reducing your energy costs.

.